Best Magnetic Separator Manufacturer in China

Best Magnetic Separator Manufacturer in China

Description:

A Magnetic Separator is a high-performance industrial device used to extract and separate ferrous particles from dry or wet materials using magnetic force. These machines play a critical role in ensuring product purity, equipment safety, and process efficiency across various industries.

Top manufacturers in China produce cutting-edge magnetic separators with a global reputation for technological innovation, precision manufacturing, and cost efficiency, offering both standard and custom solutions tailored to sectors such as mining, recycling, ceramics, pharmaceuticals, food processing, and chemicals.

Manufacturing Process:

Chinese manufacturers adopt state-of-the-art engineering and quality control systems in the production of magnetic separators.

Steps in Manufacturing:

-

Material Selection:

-

High-grade rare earth magnets (Neodymium, Ferrite)

-

Stainless steel for housings (SS304/316)

-

Precision-engineered shafts, bearings, and frames

-

-

Design & Engineering:

-

Custom CAD-based designs to meet application requirements

-

Magnetic field simulations using software tools for optimum layout

-

Component Fabrication:

-

Cutting, welding, and machining of frames, chutes, and housings

-

Coil winding and pole alignment for electromagnetic models

-

-

Magnet Assembly:

-

Manual or robotic placement of magnets into drums, plates, or grids

-

Encapsulation to protect magnets from wear and temperature

-

-

Control Integration:

-

PLC controls for automated removal, self-cleaning, or sensor-based separation

-

Integration with conveyor systems or material feeders

-

-

Testing & Calibration:

-

Magnetic strength (Gauss test), throughput, temperature resistance, and durability tests

-

Factory Acceptance Testing (FAT) and inspection certifications

-

Packaging & Dispatch:

-

Packed for export using anti-corrosion wraps, shock-absorbing materials, and protective crating

-

Applications:

-

Mining & Mineral Processing: Removing iron from ores and coal

-

Food Industry: Eliminating metal contamination from flour, sugar, spices

-

Pharmaceuticals: Ensuring ingredient purity in powders and tablets

-

Ceramics & Glass: Removing iron particles from clay and quartz

Plastics & Polymers: Purifying granules before extrusion or molding

-

Chemical Industry: Removing metallic impurities from catalysts and powder chemicals

Key Features:

Types Available: Drum type, Plate type, Overband, Grate magnets, Hump magnets, Roller separators

-

Self-Cleaning Mechanism: Reduces manual labor and downtime

-

High Throughput Capacity: Designed for bulk material handling

-

Material Compatibility: SS316/SS304 housing for hygiene-critical industries

Dust-Proof & Moisture-Resistant: Rugged designs for harsh environments

-

Energy Efficiency: Advanced coil design for low power consumption (for electromagnets)

-

Automation Ready: Can be integrated with SCADA/PLC systems

Importance in Modern Industry:

-

Prevents Equipment Damage: Protects crushers, grinders, and extruders from metal fragments

-

Maintains Product Purity: Critical for food, pharma, and chemical standards

-

Improves Operational Efficiency: Reduces product loss and contamination rework

-

Enhances Safety: Eliminates risk of spark ignition from metal particles in explosive environments

-

Meets Compliance Requirements: Supports HACCP, GMP, and ISO quality systems

Advantages:

-

Efficient Metal Removal: Extracts even micron-sized iron particles

-

Non-Contact & Non-Invasive: No material degradation during separation

-

Low Maintenance: Self-cleaning systems reduce operator effort

-

Customizable Designs: Made to suit different flow rates and materials

-

Durability: Long-lasting magnets and anti-wear construction

-

Flexible Installation: Inline, overband, chute-mounted, or gravity-fed setups

-

Safe & Eco-Friendly: No hazardous emissions, silent operation

Wide Range of Magnetic Strengths: Suited for both coarse and fine material separation

-

Competitive Pricing: High performance at lower operational costs

-

Scalable Models: From lab-scale separators to industrial-grade installations

Why Choose a Magnetic Separator Manufacturer from China?

-

Mass Manufacturing Capability: Proven capacity for bulk production and exports

-

Advanced R&D: Use of robotics, AI-driven design, and magnetic field simulations

-

Affordable Pricing: Economical without compromising performance

-

Global Certifications: CE, ISO, and FDA-ready models

-

Fast Turnaround Time: Rapid delivery of custom and standard orders

-

Complete Systems Integration: Turnkey solutions including feeding, discharge, and automation

-

Global Service Support: Network of service centers and export partners

-

Quality Assurance: Rigid testing at each stage for guaranteed reliability

Top 10 FAQs – Magnetic Separators:

-

Q: What is the difference between permanent and electromagnetic separators?

A: Permanent separators use rare-earth magnets, while electromagnets use electric coils. The latter is suitable for heavy-duty, adjustable strength requirements. -

Q: How long do the magnets last?

A: Permanent magnets retain strength for 10+ years with minimal degradation. Q: Can separators be used with wet materials?

A: Yes, there are wet-type magnetic separators for slurry and liquid-based processing.-

Q: Are magnetic separators food-grade compatible?

A: Yes, with SS316 construction and hygienic designs, they meet FDA/HACCP norms. -

Q: Can I use one separator for different materials?

A: Ideally, it should be tuned to material properties, but interchangeable grids or settings allow flexibility. -

Q: What’s the maximum material size it can handle?

A: Drum and overband types can handle particles up to 150 mm; fine mesh units for micron-level particles. -

Q: Are Chinese machines export-compliant?

A: Leading manufacturers provide CE, ATEX, and other international certifications. Q: Do separators work in high-temperature environments?

A: Yes, specialized high-temp magnets and cooling jackets are available.-

Q: What about servicing and parts?

A: Most suppliers offer global after-sales support, spare kits, and manuals. -

Q: Can these be integrated into automated production lines?

A: Yes, with PLC integration, separators can be synchronized with conveyors and sorters.

Conclusion:

Magnetic Separators are indispensable across modern industrial sectors, ensuring product quality, equipment protection, and regulatory compliance. Choosing the best manufacturer in China offers a combination of technical excellence, affordability, global support, and robust design customization.

Whether you are in mining, food, pharma, or recycling, investing in a magnetic separator from a top-tier Chinese supplier ensures smooth operations, fewer breakdowns, and a cleaner production environment.

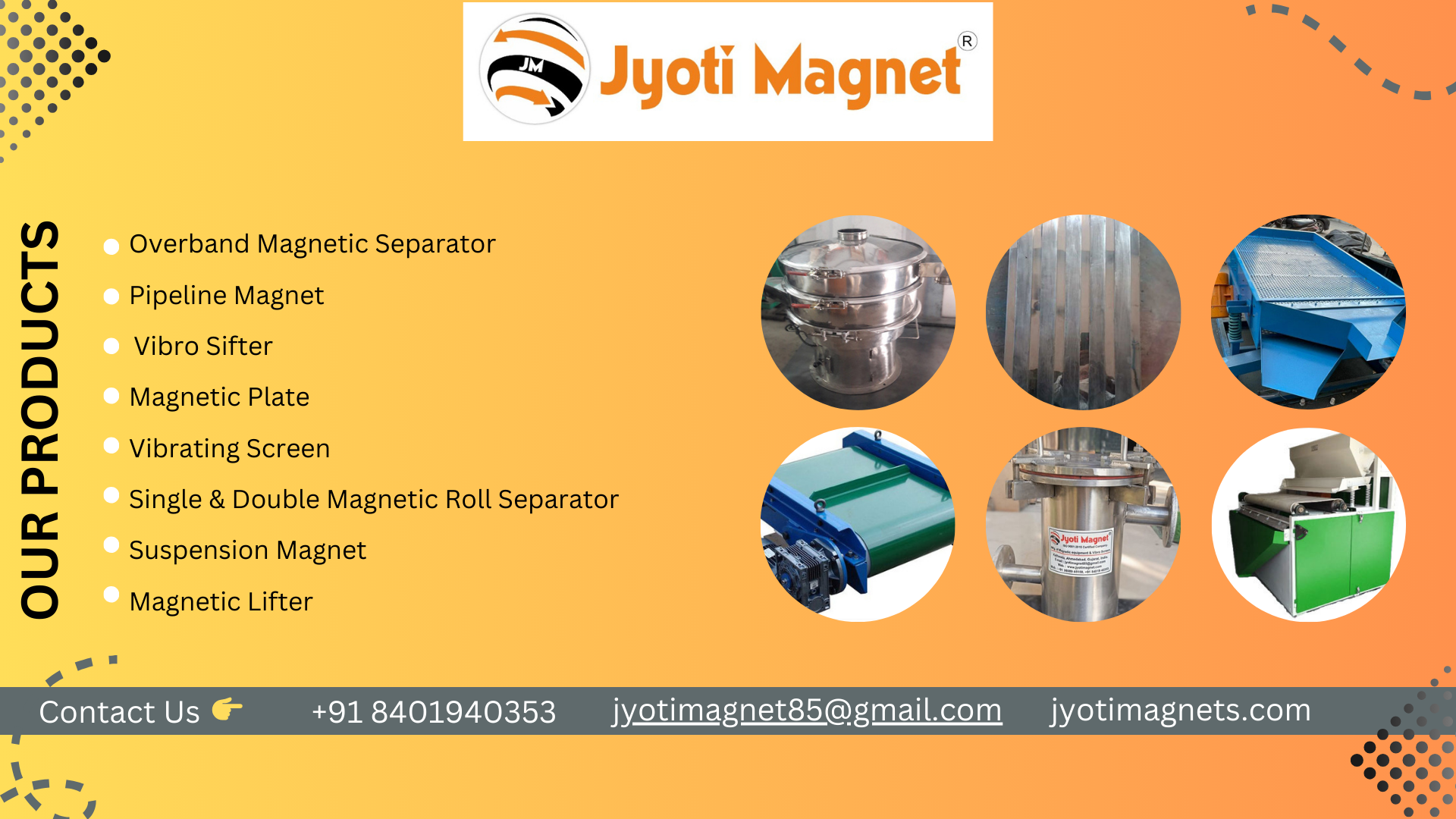

Gmail:-jyotimagnet85@gmail.com

Website:-https://jyotimagnets.com/

Filter Using Tags

Our Blogs

- Magnetic Destoner Exporter from Ahmedabad

- Trusted Magnetic Roll Separator Manufacturer in India

- Leading Magnetic Destoner Supplier in Gujarat

- Best Magnetic Roll Separator Manufacturer in Ahmedabad

- Magnetic Destoner Machine Supplier Gujarat

- Magnetic Destoner for Grain Cleaning Ahmedabad

- Industrial Magnetic Destoner Manufacturer in India

- Magnetic Destoner Supplier in Gujarat

- Magnetic Destoner Manufacturer in Ahmedabad

- Magnetic Roll Separator for Mineral Processing Gujarat

- Rare Earth Magnetic Roll Separator Manufacturer Ahmedabad

- High-Intensity Magnetic Roll Separator Manufacturer in India

- Magnetic Roll Separator Supplier in Gujarat

- Magnetic Roll Separator Manufacturer in Ahmedabad

- Top Magnetic Separator Drum Manufacturer in Gujarat

- Magnetic Drum Separator Exporter from Ahmedabad

- Trusted Magnetic Drum Separator Manufacturer in India

- Leading Magnetic Drum Separator Supplier in Gujarat

- Best Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Manufacturer in Gujarat

- Heavy Duty Magnetic Drum Separator Supplier Ahmedabad

- Magnetic Drum Separator Machine Manufacturer India

- Industrial Magnetic Drum Separator Supplier Gujarat

- Magnetic Separator Drum Manufacturer Ahmedabad

- Automatic Magnetic Drum Separator Manufacturer in India

- Magnetic Drum Separator Supplier in Gujarat

- Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Equipment Supplier

- Best Magnetic Separator Manufacturer in China

- Magnetic Roller Separator Exporter from India

- Magnetic Roll Separator Manufacturer in Gujarat

- Rare Earth Magnetic Separator

- High Intensity Magnetic Separator Supplier

- Magnetic Roll Separator

- Magnetic Roller Separator Machine?

- High Intensity Magnetic Separator Manufacturer

- Magnetic Roll Separator Manufacturer

- Dry Magnetic Separator

- High Intensity Magnetic Separator

- Magnetic Roller Separator

- Magnetic Rods Price

- Top Magnetic Rod Manufacturers

- Vibro Sifter Machine Exporter in Gujarat

- Industrial Vibro Destoner Machine

- Vibro Destoner Machine

- Automatic Vibro Destoner Machine in Ahmedabad

- Magnetic Destoner Machine Manufacturer

- Automatic Magnetic Destoner

- Hopper Magnet Manufacturer in Ahmedabad

- Magnetic Destoner Machine

- Magnetic Destoner Rod

- Magnetic Destoner Manufacturers

- Magnetic Destoner Price & Overview

- Magnetic Destoner Manufacturers Near Me

- Magnetic Destoner Manufacturers in Ahmedabad

- Magnetic Destoner Manufacturers in India

- Magnetic Destoner Manufacturer

- Leading Industrial Magnetic Equipment Manufacturer in Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Efficient Vibro Sieves Manufacturer in India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Durable Drum Pulleys Exporter from Ahmedabad

- Reliable Suspension Magnet Manufacturer in India

- High-Quality Gyro Screen Machines Supplier in Gujarat

- Magnetic Separator for Industrial Use in Ahmedabad

- Magnetic Plate and Rod Supplier in Ahmedabad

- Suspension Magnet Exporter From Ahmedabad

- Gyro Screen Machine Supplier in Gujarat

- Magnetic Equipment Manufacturer in Ahmedabad

- Magnetic Rod Supplier in Ahmedabad

- Magnetic Bar Manufacturer in India

- Industrial Magnetic Equipment Manufacturer – Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Vibro Sieve Manufacturer India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Vibro Sifter Manufacturer

- Gyro Screen Machine

- Vibro Sieve

- Vibro Screen

- Magnetic Grill

- Magnetic Tube

- Magnetic Bar

- Magnetic Rod

- Magnetic Destoner

- Magnetic Roll Separator

- Magnetic Drum Separator

- Overband Magnetic Separator

- Top Pipeline Magnet Products

- Gyro Screen Machine

- Vibro Screen

- Magnetic roll separator magnetic destoner

- Magnetic Drum Separator

- High Power Magnetic Rod

- Industrial Suspension Magnet

- Hopper Magnetic Grill

- Plate Magnet

- Magnetic Rod Manufacturers

- Super Magnetic Plate Suppliers

- Super Magnetic Plate

- Magnetic Plates Exporters

- Magnetic Plates Manufacturers Andhra Pradesh

- Magnetic Rod Suppliers

- Magnetic Rod Company

- Magnetic Plate Manufacturer

- Strong Magnetic Rod

- Magnetic Plate

- Magnetic Rod Price Manufacturer

- Magnetic Rod

- Heavy Duty Industrial Magnets

- Suspended Magnets Dealer

- Suspension Magnet Supplier

- Suspension Magnet Manufacturer

- Suspension Magnetic Separator

- Suspension Permanent Magnets

- Industrial Magnetic Grill

- Grill Magnet Manufacturer Mizoram

- Magnetic Grill Manufacturer

- Hopper Magnetic Grill

- Power Magnetic Grill

- Magnetic Grill