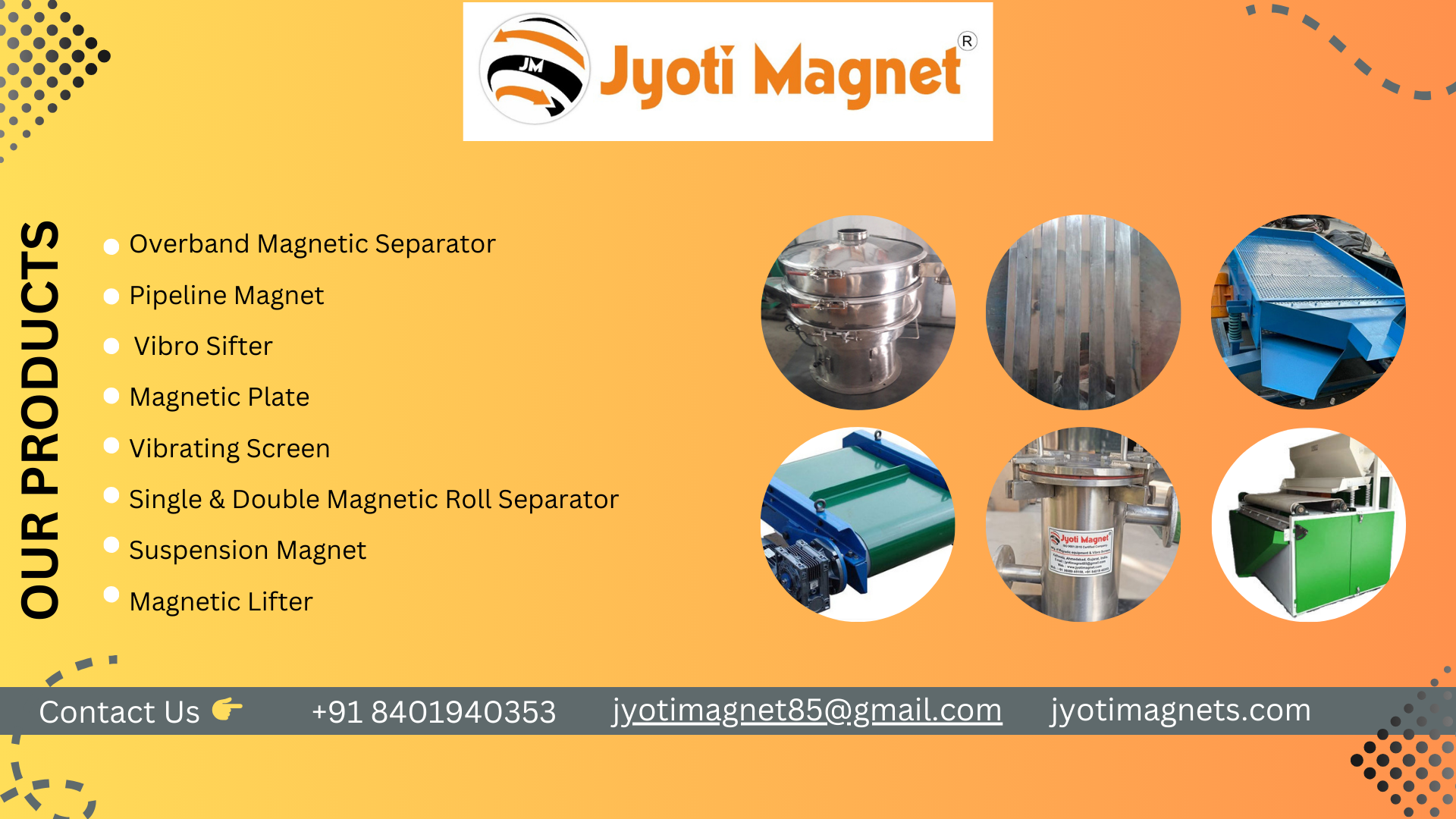

Magnetic Equipment Manufacturer in Ahmedabad

Magnetic

Equipment Manufacturer in Ahmedabad

Best

Description

Magnetic Equipment refers to a wide range of

industrial tools and machinery that use magnetic forces for separation,

lifting, detection, and filtering of metal materials. Ahmedabad is a major

manufacturing hub in India, known for its engineering excellence and

innovation in magnetic technology.

Features and Their Uses

|

Feature |

Use / Benefit |

|

High Gauss Magnetic Strength |

|

Stainless Steel Housing |

Provides corrosion resistance in food and pharma

industries |

|

Permanent & Electro Magnetic Types |

Offers flexibility based on the application (energy or

maintenance focus) |

|

Self-cleaning Mechanisms |

Reduces manual labor in continuous production lines |

|

Custom Sizes and Mounts |

Easily integrated into existing conveyors, hoppers, or

chutes |

|

Low Energy Consumption |

Makes them ideal for 24/7 operations |

|

Compact and Modular Design |

Saves space in tight installations |

|

High Throughput Handling |

Capable of processing large material volumes quickly |

|

Dust and Waterproof Enclosures |

Suitable for rough environments (mining, cement) |

|

Auto Power Cut-off Protection |

Enhances safety in electro-magnetic systems |

Applications

of Magnetic Equipment

- Mining

and Mineral Processing – Removal of iron and magnetic minerals

- Recycling

Industry – Separation of ferrous from plastic, rubber, and glass

- Food

& Beverage – Metal contaminant removal in powder, grains, liquids

- Pharmaceuticals

– Magnetic separation during tablet and capsule production

- Ceramics

and Glass – Purifying raw material by removing iron particles

- Plastics

and Polymers – Ensuring purity and preventing machine damage

- Power

Plants – Coal cleaning and ash handling systems

- Chemical

& Fertilizer Plants – Iron separation during formulation and

mixing

- Construction

– For removing steel or nails from debris or concrete

- Textile

Industries – Removal of iron particles during fiber and yarn

processing

Top 10

FAQs – Magnetic Equipment

1. What types of magnetic equipment are available?

Permanent magnets, electro magnets, drum separators, overband magnets, grills,

and pulleys.

2. Which industries use magnetic equipment?

Mining, recycling, food, pharma, ceramics, plastic, cement, chemical, and steel

industries.

3. What is the difference between permanent and

electro-magnetic equipment?

Permanent magnets require no power, while electro magnets can be controlled

and are stronger, but need power.

4. Can these machines remove very fine metal particles?

Yes, high-intensity rare-earth magnets can remove particles as small as 1

micron.

5. How is the magnetic strength measured?

In Gauss or Tesla units; higher Gauss means stronger magnetic pull.

6. Are there custom-built solutions?

Yes, most Ahmedabad manufacturers offer customized magnetic equipment to

suit conveyor sizes, material types, and application needs.

7. What maintenance is required?

Minimal for permanent types; electro-magnetic systems need occasional coiland insulation checks.

8. Is training provided for using the equipment?

Yes, most reputed companies provide installation support and operator

training.

9. How long does a magnetic separator last?

With proper care, permanent magnetic equipment can last over 10 years.

10. What is the delivery time for custom orders?

Usually between 2 to 6 weeks, depending on complexity and size.

Why

Choose Magnetic Equipment Manufacturers in Ahmedabad?

? Decades of engineeringexpertise

?

Affordable and export-grade solutions

?

ISO and CE-certified machinery

?

Wide range of magnetic technologies under one roof

?

Responsive after-sales service across India

?

Customization and integration-friendly systems

Contact

Us For More Details On :

Call - +91 84019 40353

Facebook - www.facebook.com/JyotiMagnet

Instagram - www.instagram.com/jyotimagnet_india

YouTube - www.youtube.com/@jyotimagnet1587

Website – www.jyotimagnets.com

Email - jyotimagnet85@gmail.com

Filter Using Tags

Our Blogs

- Magnetic Destoner Exporter from Ahmedabad

- Trusted Magnetic Roll Separator Manufacturer in India

- Leading Magnetic Destoner Supplier in Gujarat

- Best Magnetic Roll Separator Manufacturer in Ahmedabad

- Magnetic Destoner Machine Supplier Gujarat

- Magnetic Destoner for Grain Cleaning Ahmedabad

- Industrial Magnetic Destoner Manufacturer in India

- Magnetic Destoner Supplier in Gujarat

- Magnetic Destoner Manufacturer in Ahmedabad

- Magnetic Roll Separator for Mineral Processing Gujarat

- Rare Earth Magnetic Roll Separator Manufacturer Ahmedabad

- High-Intensity Magnetic Roll Separator Manufacturer in India

- Magnetic Roll Separator Supplier in Gujarat

- Magnetic Roll Separator Manufacturer in Ahmedabad

- Top Magnetic Separator Drum Manufacturer in Gujarat

- Magnetic Drum Separator Exporter from Ahmedabad

- Trusted Magnetic Drum Separator Manufacturer in India

- Leading Magnetic Drum Separator Supplier in Gujarat

- Best Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Manufacturer in Gujarat

- Heavy Duty Magnetic Drum Separator Supplier Ahmedabad

- Magnetic Drum Separator Machine Manufacturer India

- Industrial Magnetic Drum Separator Supplier Gujarat

- Magnetic Separator Drum Manufacturer Ahmedabad

- Automatic Magnetic Drum Separator Manufacturer in India

- Magnetic Drum Separator Supplier in Gujarat

- Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Equipment Supplier

- Best Magnetic Separator Manufacturer in China

- Magnetic Roller Separator Exporter from India

- Magnetic Roll Separator Manufacturer in Gujarat

- Rare Earth Magnetic Separator

- High Intensity Magnetic Separator Supplier

- Magnetic Roll Separator

- Magnetic Roller Separator Machine?

- High Intensity Magnetic Separator Manufacturer

- Magnetic Roll Separator Manufacturer

- Dry Magnetic Separator

- High Intensity Magnetic Separator

- Magnetic Roller Separator

- Magnetic Rods Price

- Top Magnetic Rod Manufacturers

- Vibro Sifter Machine Exporter in Gujarat

- Industrial Vibro Destoner Machine

- Vibro Destoner Machine

- Automatic Vibro Destoner Machine in Ahmedabad

- Magnetic Destoner Machine Manufacturer

- Automatic Magnetic Destoner

- Hopper Magnet Manufacturer in Ahmedabad

- Magnetic Destoner Machine

- Magnetic Destoner Rod

- Magnetic Destoner Manufacturers

- Magnetic Destoner Price & Overview

- Magnetic Destoner Manufacturers Near Me

- Magnetic Destoner Manufacturers in Ahmedabad

- Magnetic Destoner Manufacturers in India

- Magnetic Destoner Manufacturer

- Leading Industrial Magnetic Equipment Manufacturer in Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Efficient Vibro Sieves Manufacturer in India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Durable Drum Pulleys Exporter from Ahmedabad

- Reliable Suspension Magnet Manufacturer in India

- High-Quality Gyro Screen Machines Supplier in Gujarat

- Magnetic Separator for Industrial Use in Ahmedabad

- Magnetic Plate and Rod Supplier in Ahmedabad

- Suspension Magnet Exporter From Ahmedabad

- Gyro Screen Machine Supplier in Gujarat

- Magnetic Equipment Manufacturer in Ahmedabad

- Magnetic Rod Supplier in Ahmedabad

- Magnetic Bar Manufacturer in India

- Industrial Magnetic Equipment Manufacturer – Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Vibro Sieve Manufacturer India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Vibro Sifter Manufacturer

- Gyro Screen Machine

- Vibro Sieve

- Vibro Screen

- Magnetic Grill

- Magnetic Tube

- Magnetic Bar

- Magnetic Rod

- Magnetic Destoner

- Magnetic Roll Separator

- Magnetic Drum Separator

- Overband Magnetic Separator

- Top Pipeline Magnet Products

- Gyro Screen Machine

- Vibro Screen

- Magnetic roll separator magnetic destoner

- Magnetic Drum Separator

- High Power Magnetic Rod

- Industrial Suspension Magnet

- Hopper Magnetic Grill

- Plate Magnet

- Magnetic Rod Manufacturers

- Super Magnetic Plate Suppliers

- Super Magnetic Plate

- Magnetic Plates Exporters

- Magnetic Plates Manufacturers Andhra Pradesh

- Magnetic Rod Suppliers

- Magnetic Rod Company

- Magnetic Plate Manufacturer

- Strong Magnetic Rod

- Magnetic Plate

- Magnetic Rod Price Manufacturer

- Magnetic Rod

- Heavy Duty Industrial Magnets

- Suspended Magnets Dealer

- Suspension Magnet Supplier

- Suspension Magnet Manufacturer

- Suspension Magnetic Separator

- Suspension Permanent Magnets

- Industrial Magnetic Grill

- Grill Magnet Manufacturer Mizoram

- Magnetic Grill Manufacturer

- Hopper Magnetic Grill

- Power Magnetic Grill

- Magnetic Grill