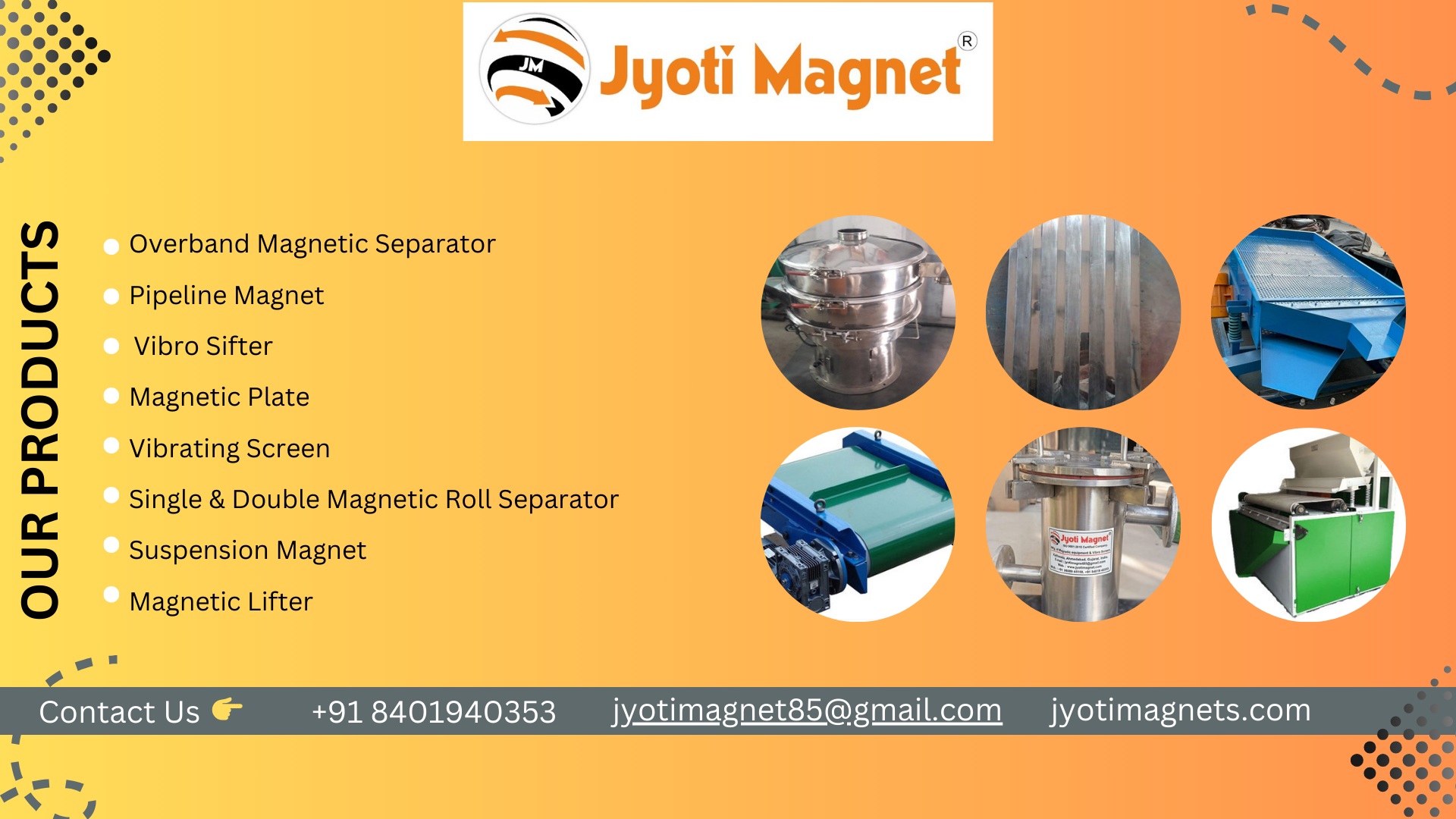

Magnetic Destoner Machine Manufacturer

Magnetic

Destoner Machine Manufacturer

Best

Description

A Magnetic Destoner Machine Manufacturer designs and

produces specialized equipment used to separate ferrous and paramagnetic

contaminants from granular materials like grains, spices, pulses, minerals, and

sand. These machines are equipped with high-intensity rare-earth magnets and

advanced vibratory systems to ensure precision separation of stones, iron

particles, and impurities.

Manufacturers in India and globally offer custom-builtMagnetic Destoners tailored for use in food processing units, flour

mills, rice mills, ceramic plants, and mineral industries. These machines

ensure purity, safety, and product quality, making them essential for

any operation requiring contaminant-free raw materials.

Top 10

FAQs Magnetic Destoner Machine Manufacturer

- What

is a magnetic destoner machine?

Its a machine that separates ferrous and paramagnetic impurities like iron, metal chips, and stones from granular products using strong magnets and vibration. - Where

is a magnetic destoner used?

In agriculture, food processing, ceramic, mining, plastic, and chemical industries for material purification. - What

is the working principle?

Material passes over a vibratory deck and high-intensity magnets attract and separate metal and stone contaminants. - What

is the magnetic intensity of the machine?

Most manufacturers use magnets with strength up to 14,000 Gauss, depending on the application. - Can

it remove non-magnetic stones?

No. Magnetic Destoners specifically remove ferrous and paramagnetic particles; for non-magnetic stones, gravity destoners are used. - What

materials can it process?

Rice, wheat, maize, pulses, spices, quartz, silica, glass, minerals, plastic granules, and more. - Does

it require maintenance?

Very low maintenance mainly cleaning magnetic plates, checking motor and vibration system. - Is

it customizable?

Yes, manufacturers offer machines with custom throughput capacities, magnet sizes, and inlet/outlet dimensions. - Is

it safe for food processing?

Yes. Food-grade stainless steel contact parts and non-toxic magnets ensure food safety. - How

do I choose the right model?

Selection is based on material type, capacity (TPH), magnetic content, and particle size.

Applications

of Magnetic Destoner Machine

- Flour

Mills & Food Grains Remove iron fillings and stones from wheat, rice, pulses

- Spice

Processing Units Clean turmeric, coriander, red chilies, pepper

- Mineral

Industries Purify quartz, silica, feldspar, mica, and glass

- Plastic

Granule Plants Separate metallic content from polymers

- Ceramic

& Tiles Manufacturing Eliminate metallic particles from raw clay

- Chemical

& Fertilizer Industries Clean chemical powders, fertilizers

- Recycling

& Waste Processing Segregate metal fragments from crushed

materials

Features

and Their Uses

|

Feature |

Use/Benefit |

|

High-Intensity Rare Earth Magnets |

Ensures efficient separation of iron and paramagnetic particles |

Vibratory Feeding System |

Evenly distributes material for consistent separation

performance |

|

Adjustable Vibration & Slope Angle |

Tailors machine for different material types and flow

rates |

|

SS 304/316 Contact Parts |

Food-grade, corrosion-resistant for food and chemical use |

|

Dust-Free Operation with Sealed Body |

Prevents contamination and ensures cleaner work

environment |

|

Easy Clean Drawer Magnets |

Enables quick maintenance and cleaning of collected

impurities |

|

Low Power Consumption Motors |

Energy-efficient and cost-saving for continuous operation |

|

Customizable Feed Hopper & Discharge |

Flexible integration into existing production lines |

|

Anti-Vibration Mounts |

Reduces noise and ensures stable machine performance |

|

Magnetic Gauss Meter Optional |

Measures field intensity for quality checks and audits |

Key

Points About Magnetic Destoner Machine Manufacturers

- Industrial

Expertise Specialized in food, minerals, and ceramic material separation

- Custom

Build Capability Machines from 0.5 TPH to 15+ TPH capacity

available

- High

Magnetic Intensity Up to 14,000 Gauss for fine particle

separation

- Durable

Construction Made with mild steel or SS304/316 based on

application

- Food-Grade

Compliant Suitable for processing edible products with safety

certifications

- Energy

Efficient Design Designed for low power consumption and long life

- Proven

Performance Consistent results in reducing product rejection and

improving quality

- ????????

Made in India Available from leading manufacturers with global

exports

- After-Sales

Support Includes installation, AMC, spare parts, and remote

troubleshooting

- Test

Facility Available Some manufacturers offer lab testing of your raw

material before purchase

Contact

Us For More Details On :

Call - +91 84019 40353

Facebook - www.facebook.com/JyotiMagnet

Instagram - www.instagram.com/jyotimagnet_india

YouTube - www.youtube.com/@jyotimagnet1587

Website www.jyotimagnets.com

Email - jyotimagnet85@gmail.com

Filter Using Tags

Our Blogs

- Magnetic Destoner Exporter from Ahmedabad

- Trusted Magnetic Roll Separator Manufacturer in India

- Leading Magnetic Destoner Supplier in Gujarat

- Best Magnetic Roll Separator Manufacturer in Ahmedabad

- Magnetic Destoner Machine Supplier Gujarat

- Magnetic Destoner for Grain Cleaning Ahmedabad

- Industrial Magnetic Destoner Manufacturer in India

- Magnetic Destoner Supplier in Gujarat

- Magnetic Destoner Manufacturer in Ahmedabad

- Magnetic Roll Separator for Mineral Processing Gujarat

- Rare Earth Magnetic Roll Separator Manufacturer Ahmedabad

- High-Intensity Magnetic Roll Separator Manufacturer in India

- Magnetic Roll Separator Supplier in Gujarat

- Magnetic Roll Separator Manufacturer in Ahmedabad

- Top Magnetic Separator Drum Manufacturer in Gujarat

- Magnetic Drum Separator Exporter from Ahmedabad

- Trusted Magnetic Drum Separator Manufacturer in India

- Leading Magnetic Drum Separator Supplier in Gujarat

- Best Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Manufacturer in Gujarat

- Heavy Duty Magnetic Drum Separator Supplier Ahmedabad

- Magnetic Drum Separator Machine Manufacturer India

- Industrial Magnetic Drum Separator Supplier Gujarat

- Magnetic Separator Drum Manufacturer Ahmedabad

- Automatic Magnetic Drum Separator Manufacturer in India

- Magnetic Drum Separator Supplier in Gujarat

- Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Equipment Supplier

- Best Magnetic Separator Manufacturer in China

- Magnetic Roller Separator Exporter from India

- Magnetic Roll Separator Manufacturer in Gujarat

- Rare Earth Magnetic Separator

- High Intensity Magnetic Separator Supplier

- Magnetic Roll Separator

- Magnetic Roller Separator Machine?

- High Intensity Magnetic Separator Manufacturer

- Magnetic Roll Separator Manufacturer

- Dry Magnetic Separator

- High Intensity Magnetic Separator

- Magnetic Roller Separator

- Magnetic Rods Price

- Top Magnetic Rod Manufacturers

- Vibro Sifter Machine Exporter in Gujarat

- Industrial Vibro Destoner Machine

- Vibro Destoner Machine

- Automatic Vibro Destoner Machine in Ahmedabad

- Magnetic Destoner Machine Manufacturer

- Automatic Magnetic Destoner

- Hopper Magnet Manufacturer in Ahmedabad

- Magnetic Destoner Machine

- Magnetic Destoner Rod

- Magnetic Destoner Manufacturers

- Magnetic Destoner Price & Overview

- Magnetic Destoner Manufacturers Near Me

- Magnetic Destoner Manufacturers in Ahmedabad

- Magnetic Destoner Manufacturers in India

- Magnetic Destoner Manufacturer

- Leading Industrial Magnetic Equipment Manufacturer in Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Efficient Vibro Sieves Manufacturer in India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Durable Drum Pulleys Exporter from Ahmedabad

- Reliable Suspension Magnet Manufacturer in India

- High-Quality Gyro Screen Machines Supplier in Gujarat

- Magnetic Separator for Industrial Use in Ahmedabad

- Magnetic Plate and Rod Supplier in Ahmedabad

- Suspension Magnet Exporter From Ahmedabad

- Gyro Screen Machine Supplier in Gujarat

- Magnetic Equipment Manufacturer in Ahmedabad

- Magnetic Rod Supplier in Ahmedabad

- Magnetic Bar Manufacturer in India

- Industrial Magnetic Equipment Manufacturer Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Vibro Sieve Manufacturer India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Vibro Sifter Manufacturer

- Gyro Screen Machine

- Vibro Sieve

- Vibro Screen

- Magnetic Grill

- Magnetic Tube

- Magnetic Bar

- Magnetic Rod

- Magnetic Destoner

- Magnetic Roll Separator

- Magnetic Drum Separator

- Overband Magnetic Separator

- Top Pipeline Magnet Products

- Gyro Screen Machine

- Vibro Screen

- Magnetic roll separator magnetic destoner

- Magnetic Drum Separator

- High Power Magnetic Rod

- Industrial Suspension Magnet

- Hopper Magnetic Grill

- Plate Magnet

- Magnetic Rod Manufacturers

- Super Magnetic Plate Suppliers

- Super Magnetic Plate

- Magnetic Plates Exporters

- Magnetic Plates Manufacturers Andhra Pradesh

- Magnetic Rod Suppliers

- Magnetic Rod Company

- Magnetic Plate Manufacturer

- Strong Magnetic Rod

- Magnetic Plate

- Magnetic Rod Price Manufacturer

- Magnetic Rod

- Heavy Duty Industrial Magnets

- Suspended Magnets Dealer

- Suspension Magnet Supplier

- Suspension Magnet Manufacturer

- Suspension Magnetic Separator

- Suspension Permanent Magnets

- Industrial Magnetic Grill

- Grill Magnet Manufacturer Mizoram

- Magnetic Grill Manufacturer

- Hopper Magnetic Grill

- Power Magnetic Grill

- Magnetic Grill