Magnetic Roll Separator Manufacturer in Gujarat

Magnetic Roll Separator Manufacturer in Gujarat

Introduction

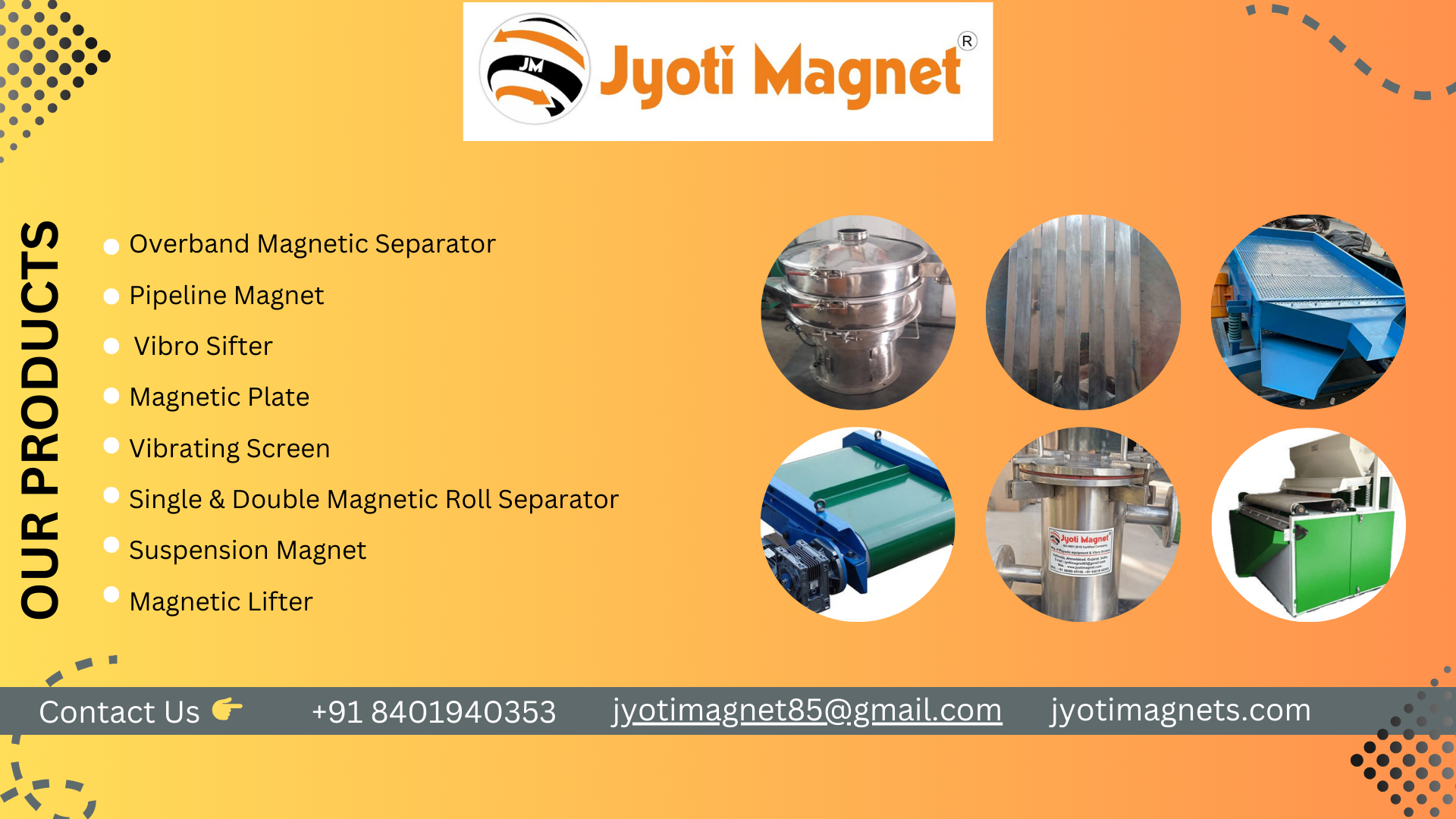

A Magnetic Roll Separator is a high-intensity magnetic separation machine used to remove fine ferrous and paramagnetic particles from dry materials like minerals, chemicals, food products, plastics, ceramics, and abrasives. It works on the principle of magnetic attraction and repulsion, offering powerful separation without contamination or chemical processing.

Gujarat, being one of India's leading industrial states with a strong base in mineral processing, ceramics, chemicals, and plastic recycling, is home to several reputed manufacturers producing high-quality Magnetic Roll Separators for domestic and global markets.

What is a Magnetic Roll Separator?

A Magnetic Roll Separator is an industrial machine that uses rare-earth permanent magnets mounted on a rotating roll to attract and separate magnetic materials from non-magnetic ones. It is used especially for separating very fine or weakly magnetic materials in dry form.

How It's Made (Manufacturing Process)

The construction of a magnetic roll separator involves precision engineering, material science, and magnetic field calculations. Here's a step-by-step view:

1. Design & Engineering

-

Calculation of magnetic field gradient (up to 20,000 Gauss or more)

CAD modeling of the roll system, feed system, and discharge assembly

-

Selection of materials: neodymium magnets, stainless steel, and Teflon coating

2. Components Used

-

Magnetic Roll Assembly: Made of rare earth magnets (NdFeB)

-

Non-Magnetic Roll Shell: High-speed stainless steel sleeve

-

Vibratory Feeder/Material Feeder

-

Splitter System: To collect magnetic and non-magnetic outputs

-

Drive Motor with Gearbox

-

Support Frame: Mild steel or stainless steel

-

Discharge Chutes and Dust Cover

-

Control Panel (optional): For speed and feeder control

3. Assembly Process

Mounting of feeder system with adjustable tray angle

-

Integration of discharge chutes with customizable splitter blades

-

Motor alignment and belt/pulley coupling

-

Final machine enclosure with protective covers

4. Testing

Vibration and noise level check

-

Trial run with test materials (e.g., quartz or feldspar)

-

Inspection of separation efficiency

Where It's Used

Magnetic Roll Separators are essential in industries dealing with dry, granular, or powdered materials. Common applications in Gujarat and beyond include:

-

Mineral Processing (quartz, feldspar, bauxite, kaolin)

-

Plastic Recycling (PET Flake Purification)

-

Chemical and Fertilizer Plants

-

Abrasives Manufacturing

-

Food Industry (spices and grains cleaning)

-

Foundries (removal of iron from silica sand)

Key Features

-

High Magnetic Intensity: Up to 20,000+ Gauss

Compact Design: Space-saving and modular

-

Stainless Steel Construction: Corrosion-resistant and durable

-

Adjustable Splitters: For precise separation

-

High-Speed Roll Operation: For maximum throughput

-

Efficient Dry Separation: No water or chemicals required

-

Continuous Operation: Suitable for 24/7 industrial use

Vibration-Free Feeding System: Uniform material flow

Importance in Material Processing

-

Purification of Raw Materials: Removes iron from quartz, silica, and other minerals

Protects Downstream Equipment: Prevents damage to crushers and grinders

-

Ensures Product Quality: Critical in ceramics, food, and plastics

-

Saves Operational Costs: Dry separation eliminates water usage and sludge disposal

-

Enables Recycling: Vital for clean separation in e-waste and plastic industries

Advantages

Feature |

Advantage |

|---|---|

| High Magnetic Strength | Removes even weakly magnetic impurities like hematite, ilmenite |

| Low Maintenance | No moving parts in magnetic roll itself |

| Eco-Friendly Operation | No water or chemicals needed |

| Durable and Long-Lasting | |

| Flexible Feed Size | Handles material sizes from 0.1 mm to 5 mm |

| Easy Installation | Plug-and-play format with minimal civil work |

| Precision Separation | |

| Cost-Effective | Reduces need for manual cleaning and rejection |

Significance for Gujarat-Based Industries

-

Gujarat is a leader in ceramic tile production, mineral mining, chemical processing, and plastics recycling.

Local manufacturers in cities like Ahmedabad, Rajkot, Bhuj, Morbi, and Vadodara supply magnetic roll separators tailored for Indian materials and conditions.

-

Export quality manufacturing: Many units in Gujarat produce equipment compliant with CE and ISO standards, suitable for global use.

-

Strong after-sales service network ensures minimal downtime and easy parts availability.

Why Choose a Magnetic Roll Separator from Gujarat?

Local Manufacturing + Global Quality

Affordable Pricing with Customization

Quick Delivery and Spare Support

Built for Indian Materials (bauxite, quartz, etc.)

Test Facilities for Customer Samples

Trusted by Top Ceramic, Plastic, and Mining Firms

FAQs

Q1: What is the typical magnetic intensity of these separators?

Most Gujarat-made machines range from 10,000 to 24,000 Gauss, depending on the model.

Q2: What materials can it remove iron from?

Quartz, silica, feldspar, plastics, abrasives, kaolin, food grains, and more.

Q3: Does it require water or chemicals?

No. It's a dry separation process, making it eco-friendly.

Q4: Is it suitable for fine powder?

Yes, especially when using high-speed rolls and vibratory feeders.

Q5: Can I test my sample before purchase?

Yes. Most manufacturers offer demo trials with your material.

Conclusion

A Magnetic Roll Separator is not just a piece of equipment—it's an essential process tool that ensures purity, efficiency, and protection in modern material processing. Whether you're in minerals, plastics, ceramics, or chemicals, investing in this machine improves product quality, reduces waste, and saves energy.

Manufacturers in Gujarat are known for delivering robust, high-efficiency machines tailored for Indian industry needs—with strong local support and global-grade performance. If you're looking for clean, cost-effective, and continuous magnetic separation, the Gujarat-made magnetic roll separator is your smart choice.

Gmail:-jyotimagnet85@gmail.com

Website:-https://jyotimagnets.com/

Filter Using Tags

Our Blogs

- Magnetic Destoner Exporter from Ahmedabad

- Trusted Magnetic Roll Separator Manufacturer in India

- Leading Magnetic Destoner Supplier in Gujarat

- Best Magnetic Roll Separator Manufacturer in Ahmedabad

- Magnetic Destoner Machine Supplier Gujarat

- Magnetic Destoner for Grain Cleaning Ahmedabad

- Industrial Magnetic Destoner Manufacturer in India

- Magnetic Destoner Supplier in Gujarat

- Magnetic Destoner Manufacturer in Ahmedabad

- Magnetic Roll Separator for Mineral Processing Gujarat

- Rare Earth Magnetic Roll Separator Manufacturer Ahmedabad

- High-Intensity Magnetic Roll Separator Manufacturer in India

- Magnetic Roll Separator Supplier in Gujarat

- Magnetic Roll Separator Manufacturer in Ahmedabad

- Top Magnetic Separator Drum Manufacturer in Gujarat

- Magnetic Drum Separator Exporter from Ahmedabad

- Trusted Magnetic Drum Separator Manufacturer in India

- Leading Magnetic Drum Separator Supplier in Gujarat

- Best Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Manufacturer in Gujarat

- Heavy Duty Magnetic Drum Separator Supplier Ahmedabad

- Magnetic Drum Separator Machine Manufacturer India

- Industrial Magnetic Drum Separator Supplier Gujarat

- Magnetic Separator Drum Manufacturer Ahmedabad

- Automatic Magnetic Drum Separator Manufacturer in India

- Magnetic Drum Separator Supplier in Gujarat

- Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Equipment Supplier

- Best Magnetic Separator Manufacturer in China

- Magnetic Roller Separator Exporter from India

- Magnetic Roll Separator Manufacturer in Gujarat

- Rare Earth Magnetic Separator

- High Intensity Magnetic Separator Supplier

- Magnetic Roll Separator

- Magnetic Roller Separator Machine?

- High Intensity Magnetic Separator Manufacturer

- Magnetic Roll Separator Manufacturer

- Dry Magnetic Separator

- High Intensity Magnetic Separator

- Magnetic Roller Separator

- Magnetic Rods Price

- Top Magnetic Rod Manufacturers

- Vibro Sifter Machine Exporter in Gujarat

- Industrial Vibro Destoner Machine

- Vibro Destoner Machine

- Automatic Vibro Destoner Machine in Ahmedabad

- Magnetic Destoner Machine Manufacturer

- Automatic Magnetic Destoner

- Hopper Magnet Manufacturer in Ahmedabad

- Magnetic Destoner Machine

- Magnetic Destoner Rod

- Magnetic Destoner Manufacturers

- Magnetic Destoner Price & Overview

- Magnetic Destoner Manufacturers Near Me

- Magnetic Destoner Manufacturers in Ahmedabad

- Magnetic Destoner Manufacturers in India

- Magnetic Destoner Manufacturer

- Leading Industrial Magnetic Equipment Manufacturer in Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Efficient Vibro Sieves Manufacturer in India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Durable Drum Pulleys Exporter from Ahmedabad

- Reliable Suspension Magnet Manufacturer in India

- High-Quality Gyro Screen Machines Supplier in Gujarat

- Magnetic Separator for Industrial Use in Ahmedabad

- Magnetic Plate and Rod Supplier in Ahmedabad

- Suspension Magnet Exporter From Ahmedabad

- Gyro Screen Machine Supplier in Gujarat

- Magnetic Equipment Manufacturer in Ahmedabad

- Magnetic Rod Supplier in Ahmedabad

- Magnetic Bar Manufacturer in India

- Industrial Magnetic Equipment Manufacturer – Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Vibro Sieve Manufacturer India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Vibro Sifter Manufacturer

- Gyro Screen Machine

- Vibro Sieve

- Vibro Screen

- Magnetic Grill

- Magnetic Tube

- Magnetic Bar

- Magnetic Rod

- Magnetic Destoner

- Magnetic Roll Separator

- Magnetic Drum Separator

- Overband Magnetic Separator

- Top Pipeline Magnet Products

- Gyro Screen Machine

- Vibro Screen

- Magnetic roll separator magnetic destoner

- Magnetic Drum Separator

- High Power Magnetic Rod

- Industrial Suspension Magnet

- Hopper Magnetic Grill

- Plate Magnet

- Magnetic Rod Manufacturers

- Super Magnetic Plate Suppliers

- Super Magnetic Plate

- Magnetic Plates Exporters

- Magnetic Plates Manufacturers Andhra Pradesh

- Magnetic Rod Suppliers

- Magnetic Rod Company

- Magnetic Plate Manufacturer

- Strong Magnetic Rod

- Magnetic Plate

- Magnetic Rod Price Manufacturer

- Magnetic Rod

- Heavy Duty Industrial Magnets

- Suspended Magnets Dealer

- Suspension Magnet Supplier

- Suspension Magnet Manufacturer

- Suspension Magnetic Separator

- Suspension Permanent Magnets

- Industrial Magnetic Grill

- Grill Magnet Manufacturer Mizoram

- Magnetic Grill Manufacturer

- Hopper Magnetic Grill

- Power Magnetic Grill

- Magnetic Grill