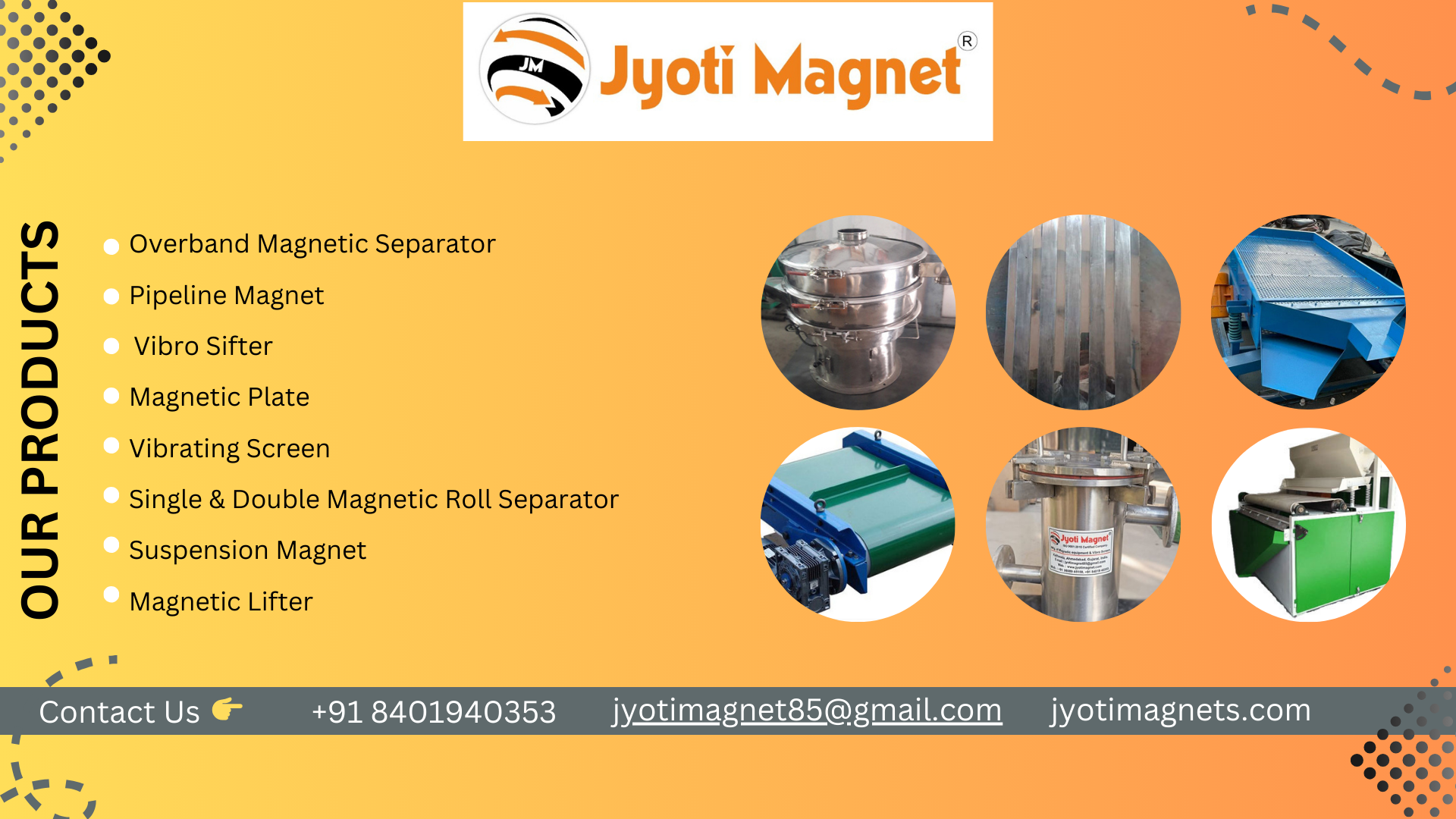

Magnetic Separator Equipment Supplier

Magnetic Separator Equipment Supplier

Description

A Magnetic Separator is a device that uses magnetic forces to separate magnetic materials from non-magnetic substances in various industries. Suppliers of this equipment specialize in designing and manufacturing robust and efficient magnetic separation systems tailored to specific industrial needs, ensuring contamination-free processes and improved product quality.

Manufacturing Process

The manufacturing of magnetic separators involves several precise engineering steps:

-

Material Selection: High-grade stainless steel and powerful rare-earth magnets (like Neodymium or Ferrite) are selected.

-

Design Engineering: Custom CAD models are developed based on the separation requirement, capacity, and material flow.

-

Magnet Assembly: Magnets are encapsulated within stainless steel cartridges or placed in drum housings.

-

Fabrication: The separator housing, drums, or grids are fabricated and welded.

-

Magnetic Strength Testing: Each unit is tested for consistent Gauss strength.

-

Surface Finishing: Equipment is polished or coated to resist corrosion.

Applications

Magnetic separators are widely used in multiple industries including:

-

Food Processing – Removal of ferrous contaminants from grains, spices, and dairy powders.

-

Mining and Mineral Processing – Extracting magnetic ores or removing metal debris from ores.

-

Recycling – Sorting metals in recycling plants.

-

Pharmaceuticals – Ensuring purity by removing metal particles from powders and liquids.

Ceramics and Glass – Removing iron particles that can affect product quality.

-

Chemical Processing – Maintaining product consistency and machinery protection.

Key Features

-

High magnetic field strength and uniform distribution.

Easy installation and low maintenance.

-

Manual or automatic cleaning options.

-

Customizable designs: drum, grid, drawer, overband, or suspension types.

-

Compact design with high separation efficiency.

Importance

Magnetic separators are vital in modern industries for:

-

Ensuring product safety and compliance with quality standards.

-

Reducing equipment wear and maintenance by removing metal debris.

Increasing process efficiency and reducing waste.

Advantages

-

Non-invasive and continuous separation.

-

Energy-efficient operation.

-

Long service life with durable magnets.

-

Minimal operational downtime due to easy maintenance.

-

Eco-friendly solution to industrial metal contamination.

-

Improved profitability through quality enhancement and reduced machine damage.

Significance

The adoption of magnetic separator equipment demonstrates a company’s commitment to product excellence and operational efficiency. It helps industries meet stringent quality and safety regulations, which is particularly crucial in food, pharma, and chemical sectors.

Why Choose a Reliable Magnetic Separator Supplier?

Quality Materials: Use of high-performance magnets and durable fabrication ensures longevity.

-

Tailored Solutions: Options for industry-specific requirements and throughput volumes.

-

After-Sales Support: Timely maintenance, spare parts, and technical guidance.

-

Cost-Effective Systems: Optimized design for maximum performance at competitive prices.

FAQs

Q1: What types of magnetic separators are available?

A1: Drum, overband, suspension, plate, grid, drawer, and liquid line magnetic separators.

Q2: How do I choose the right separator for my application?

A2: Based on the material type, particle size, flow rate, contamination level, and installation layout.

Q3: What maintenance is required?

A3: Regular cleaning of the magnetic surface and periodic magnetic strength checks.

Q4: Are magnetic separators safe for food-grade applications?

A4: Yes, food-grade separators use stainless steel and sanitary designs approved for food contact.

Q5: Can separators be integrated into automated systems?

A5: Absolutely, many models come with automatic cleaning and PLC-compatible controls.

Conclusion

Magnetic separator equipment plays a pivotal role in ensuring the purity, safety, and efficiency of industrial processes. Partnering with a trustworthy supplier guarantees advanced engineering, durable products, and customized solutions tailored to your operational needs. Investing in magnetic separation technology is not just a process enhancement—it's a commitment to excellence.

Contact:-+91 8401940353

Filter Using Tags

Our Blogs

- Magnetic Destoner Exporter from Ahmedabad

- Trusted Magnetic Roll Separator Manufacturer in India

- Leading Magnetic Destoner Supplier in Gujarat

- Best Magnetic Roll Separator Manufacturer in Ahmedabad

- Magnetic Destoner Machine Supplier Gujarat

- Magnetic Destoner for Grain Cleaning Ahmedabad

- Industrial Magnetic Destoner Manufacturer in India

- Magnetic Destoner Supplier in Gujarat

- Magnetic Destoner Manufacturer in Ahmedabad

- Magnetic Roll Separator for Mineral Processing Gujarat

- Rare Earth Magnetic Roll Separator Manufacturer Ahmedabad

- High-Intensity Magnetic Roll Separator Manufacturer in India

- Magnetic Roll Separator Supplier in Gujarat

- Magnetic Roll Separator Manufacturer in Ahmedabad

- Top Magnetic Separator Drum Manufacturer in Gujarat

- Magnetic Drum Separator Exporter from Ahmedabad

- Trusted Magnetic Drum Separator Manufacturer in India

- Leading Magnetic Drum Separator Supplier in Gujarat

- Best Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Manufacturer in Gujarat

- Heavy Duty Magnetic Drum Separator Supplier Ahmedabad

- Magnetic Drum Separator Machine Manufacturer India

- Industrial Magnetic Drum Separator Supplier Gujarat

- Magnetic Separator Drum Manufacturer Ahmedabad

- Automatic Magnetic Drum Separator Manufacturer in India

- Magnetic Drum Separator Supplier in Gujarat

- Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Equipment Supplier

- Best Magnetic Separator Manufacturer in China

- Magnetic Roller Separator Exporter from India

- Magnetic Roll Separator Manufacturer in Gujarat

- Rare Earth Magnetic Separator

- High Intensity Magnetic Separator Supplier

- Magnetic Roll Separator

- Magnetic Roller Separator Machine?

- High Intensity Magnetic Separator Manufacturer

- Magnetic Roll Separator Manufacturer

- Dry Magnetic Separator

- High Intensity Magnetic Separator

- Magnetic Roller Separator

- Magnetic Rods Price

- Top Magnetic Rod Manufacturers

- Vibro Sifter Machine Exporter in Gujarat

- Industrial Vibro Destoner Machine

- Vibro Destoner Machine

- Automatic Vibro Destoner Machine in Ahmedabad

- Magnetic Destoner Machine Manufacturer

- Automatic Magnetic Destoner

- Hopper Magnet Manufacturer in Ahmedabad

- Magnetic Destoner Machine

- Magnetic Destoner Rod

- Magnetic Destoner Manufacturers

- Magnetic Destoner Price & Overview

- Magnetic Destoner Manufacturers Near Me

- Magnetic Destoner Manufacturers in Ahmedabad

- Magnetic Destoner Manufacturers in India

- Magnetic Destoner Manufacturer

- Leading Industrial Magnetic Equipment Manufacturer in Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Efficient Vibro Sieves Manufacturer in India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Durable Drum Pulleys Exporter from Ahmedabad

- Reliable Suspension Magnet Manufacturer in India

- High-Quality Gyro Screen Machines Supplier in Gujarat

- Magnetic Separator for Industrial Use in Ahmedabad

- Magnetic Plate and Rod Supplier in Ahmedabad

- Suspension Magnet Exporter From Ahmedabad

- Gyro Screen Machine Supplier in Gujarat

- Magnetic Equipment Manufacturer in Ahmedabad

- Magnetic Rod Supplier in Ahmedabad

- Magnetic Bar Manufacturer in India

- Industrial Magnetic Equipment Manufacturer – Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Vibro Sieve Manufacturer India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Vibro Sifter Manufacturer

- Gyro Screen Machine

- Vibro Sieve

- Vibro Screen

- Magnetic Grill

- Magnetic Tube

- Magnetic Bar

- Magnetic Rod

- Magnetic Destoner

- Magnetic Roll Separator

- Magnetic Drum Separator

- Overband Magnetic Separator

- Top Pipeline Magnet Products

- Gyro Screen Machine

- Vibro Screen

- Magnetic roll separator magnetic destoner

- Magnetic Drum Separator

- High Power Magnetic Rod

- Industrial Suspension Magnet

- Hopper Magnetic Grill

- Plate Magnet

- Magnetic Rod Manufacturers

- Super Magnetic Plate Suppliers

- Super Magnetic Plate

- Magnetic Plates Exporters

- Magnetic Plates Manufacturers Andhra Pradesh

- Magnetic Rod Suppliers

- Magnetic Rod Company

- Magnetic Plate Manufacturer

- Strong Magnetic Rod

- Magnetic Plate

- Magnetic Rod Price Manufacturer

- Magnetic Rod

- Heavy Duty Industrial Magnets

- Suspended Magnets Dealer

- Suspension Magnet Supplier

- Suspension Magnet Manufacturer

- Suspension Magnetic Separator

- Suspension Permanent Magnets

- Industrial Magnetic Grill

- Grill Magnet Manufacturer Mizoram

- Magnetic Grill Manufacturer

- Hopper Magnetic Grill

- Power Magnetic Grill

- Magnetic Grill