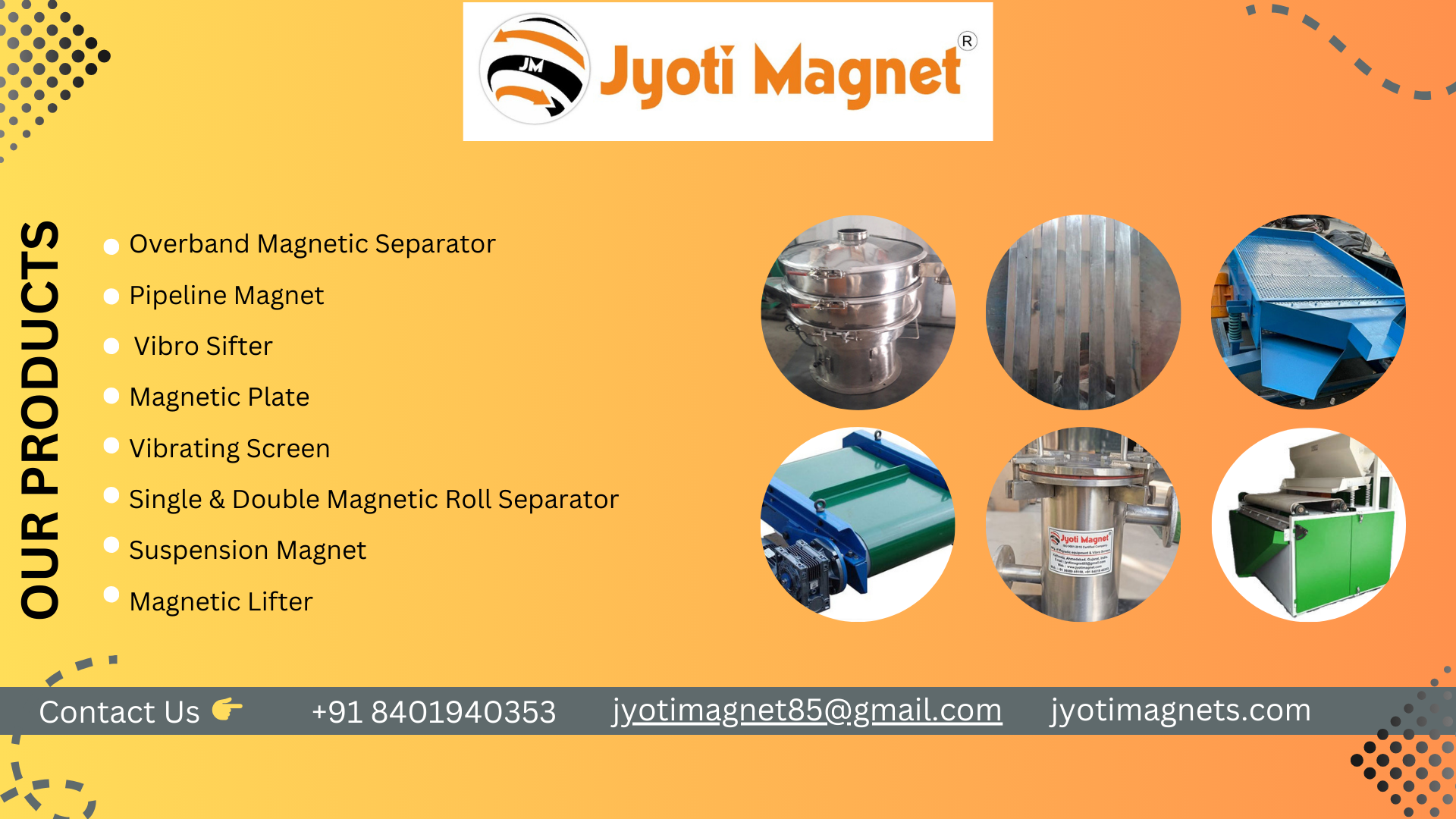

Magnetic Plate and Rod Manufacturer in Gujarat

Magnetic

Plate and Rod Manufacturer in Gujarat

As a leading Magnetic Plate and Rod Manufacturer inGujarat, we specialize in designing and supplying premium-quality magnetic

separation components that ensure the efficient removal of ferrous

contaminants from raw materials. Our Magnetic Plates and Magnetic

Rods (also called Magnetic Filters or Bars) are widely used in industries

like food processing, pharmaceuticals, plastics, chemicals, minerals, and

recycling to ensure product purity and protect machinery from metal damage.

Crafted using high-intensity rare-earth magnets(Neodymium or Ferrite), our products are corrosion-resistant, easy to

clean, and highly durable, even in high-temperature or high-moisture

environments. We offer both standard and custom designs, available in round,

square, or flat configurations for hopper, chute, or pipeline

installations.

Key

Features & Their Uses

|

Feature |

Use / Function |

|

High-Intensity Magnetic Field |

Captures even fine iron particles and metal fragments from

materials. |

|

Neodymium or Ferrite Magnets |

Offers options for high or medium strength magnetic

separation. |

|

Stainless Steel (SS304/SS316) Casing |

Protects magnets and ensures hygienic, rust-free

performance. |

|

Welded/Sealed Housing |

Prevents contamination and is easy to clean manually or

with CIP systems. |

|

Custom Size and Shape |

Fits seamlessly into hoppers, pipes, chutes, and process

lines. |

|

Easy to Install and Remove |

Quick retrofitting without requiring system modifications. |

|

Temperature Resistant |

Operates effectively in conditions up to 350°C (based on

magnet type). |

|

Non-Electric Operation |

No power supply neededfully passive and energy-efficient. |

|

Available in Plate or Rod Form |

Suitable for gravity flow systems or inline use. |

|

Low Maintenance |

Simple surface cleaning ensures long service life. |

Applications

of Magnetic Plates and Rods

- Food

Processing Remove ferrous dust and metal bits from grains, spices, flour, and pulses.

- Pharmaceutical

Industry Prevent contamination in tablet and powder processing.

- Plastic

Granule Manufacturing Clean raw plastic pellets before extrusion or

molding.

- Minerals

& Ceramics Purify feldspar, quartz, and silica in powder form.

- Chemical

Industry Clean powder, liquid, and slurry mixtures during

processing.

- Textile

& Nonwoven Industry Remove metallic contaminants in fiber and

web lines.

- Recycling

Plants Separate ferrous contaminants from plastic, glass, and

e-waste.

- Paper

& Pulp Industry Remove staples and iron debris from pulp

slurries.

- Cement

& Construction Materials Remove nails and iron filings from raw

mix.

- Biscuit/Confectionery

Lines Ensure safe, metal-free edible products in continuous lines.

Top 10

FAQs about Magnetic Plate and Rod Manufacturer in Gujarat

1. What is the difference between magnetic plates and

rods?

Plates are flat magnets used in chutes or conveyors, while rods (or bars) are

cylindrical and used in hoppers, pipes, and filters.

2. What materials are used in your magnetic products?

We use Neodymium (NdFeB) and Ferrite magnets encased in SS304 or SS316

stainless steel.

3. Are your magnets food-grade and safe for

pharmaceuticals?

Yes, we manufacture magnetic rods and plates suitable for GMP and

HACCP-compliant environments.

4. What is the standard magnetic strength?

Neodymium rods can range from 9000 to 12000 Gauss, and ferrite options

range between 20003000 Gauss.

5. Can I get custom dimensions or mounting styles?

Absolutely. We offer full customization based on application, size, and

material flow type.

6. Do you provide magnetic grills or magnetic traps too?

Yes, we manufacture magnetic grills, traps, housings, and separators

using magnetic rods.

7. How do I clean these magnetic separators?

They are cleaned by wiping or sliding collected ferrous material off the

surface. Self-cleaning models are available on request.

8. Are your products suitable for high temperatures?

Yes. Ferrite models withstand up to 350°C, while Neodymium options are rated

for up to 80150°C.

9. What industries use your magnetic rods and plates?

Food, pharma, chemical, minerals, plastics, ceramics, recycling, and more.

10. Do you export magnetic rods and plates?

Yes, we export to the Middle East, Africa, Southeast Asia, and Europe.

Why

Choose Us as Your Magnetic Plate and Rod Manufacturer in Gujarat?

- In-House Manufacturing with Custom Design Support

- ISO-Certified

& GMP-Compliant Products

- High

Magnetic Strength with Proven Durability

- Export-Quality

Finish & Packaging

- Pan-India

Supply & Global Export Reach

- Bulk

Supply for OEMs, Traders & End Users

Contact

Us For More Details On :

Call - +91 84019 40353

Facebook - www.facebook.com/JyotiMagnet

Instagram - www.instagram.com/jyotimagnet_india

YouTube - www.youtube.com/@jyotimagnet1587

Website www.jyotimagnets.com

Email - jyotimagnet85@gmail.com

Filter Using Tags

Our Blogs

- Magnetic Destoner Exporter from Ahmedabad

- Trusted Magnetic Roll Separator Manufacturer in India

- Leading Magnetic Destoner Supplier in Gujarat

- Best Magnetic Roll Separator Manufacturer in Ahmedabad

- Magnetic Destoner Machine Supplier Gujarat

- Magnetic Destoner for Grain Cleaning Ahmedabad

- Industrial Magnetic Destoner Manufacturer in India

- Magnetic Destoner Supplier in Gujarat

- Magnetic Destoner Manufacturer in Ahmedabad

- Magnetic Roll Separator for Mineral Processing Gujarat

- Rare Earth Magnetic Roll Separator Manufacturer Ahmedabad

- High-Intensity Magnetic Roll Separator Manufacturer in India

- Magnetic Roll Separator Supplier in Gujarat

- Magnetic Roll Separator Manufacturer in Ahmedabad

- Top Magnetic Separator Drum Manufacturer in Gujarat

- Magnetic Drum Separator Exporter from Ahmedabad

- Trusted Magnetic Drum Separator Manufacturer in India

- Leading Magnetic Drum Separator Supplier in Gujarat

- Best Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Manufacturer in Gujarat

- Heavy Duty Magnetic Drum Separator Supplier Ahmedabad

- Magnetic Drum Separator Machine Manufacturer India

- Industrial Magnetic Drum Separator Supplier Gujarat

- Magnetic Separator Drum Manufacturer Ahmedabad

- Automatic Magnetic Drum Separator Manufacturer in India

- Magnetic Drum Separator Supplier in Gujarat

- Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Equipment Supplier

- Best Magnetic Separator Manufacturer in China

- Magnetic Roller Separator Exporter from India

- Magnetic Roll Separator Manufacturer in Gujarat

- Rare Earth Magnetic Separator

- High Intensity Magnetic Separator Supplier

- Magnetic Roll Separator

- Magnetic Roller Separator Machine?

- High Intensity Magnetic Separator Manufacturer

- Magnetic Roll Separator Manufacturer

- Dry Magnetic Separator

- High Intensity Magnetic Separator

- Magnetic Roller Separator

- Magnetic Rods Price

- Top Magnetic Rod Manufacturers

- Vibro Sifter Machine Exporter in Gujarat

- Industrial Vibro Destoner Machine

- Vibro Destoner Machine

- Automatic Vibro Destoner Machine in Ahmedabad

- Magnetic Destoner Machine Manufacturer

- Automatic Magnetic Destoner

- Hopper Magnet Manufacturer in Ahmedabad

- Magnetic Destoner Machine

- Magnetic Destoner Rod

- Magnetic Destoner Manufacturers

- Magnetic Destoner Price & Overview

- Magnetic Destoner Manufacturers Near Me

- Magnetic Destoner Manufacturers in Ahmedabad

- Magnetic Destoner Manufacturers in India

- Magnetic Destoner Manufacturer

- Leading Industrial Magnetic Equipment Manufacturer in Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Efficient Vibro Sieves Manufacturer in India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Durable Drum Pulleys Exporter from Ahmedabad

- Reliable Suspension Magnet Manufacturer in India

- High-Quality Gyro Screen Machines Supplier in Gujarat

- Magnetic Separator for Industrial Use in Ahmedabad

- Magnetic Plate and Rod Supplier in Ahmedabad

- Suspension Magnet Exporter From Ahmedabad

- Gyro Screen Machine Supplier in Gujarat

- Magnetic Equipment Manufacturer in Ahmedabad

- Magnetic Rod Supplier in Ahmedabad

- Magnetic Bar Manufacturer in India

- Industrial Magnetic Equipment Manufacturer Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Vibro Sieve Manufacturer India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Vibro Sifter Manufacturer

- Gyro Screen Machine

- Vibro Sieve

- Vibro Screen

- Magnetic Grill

- Magnetic Tube

- Magnetic Bar

- Magnetic Rod

- Magnetic Destoner

- Magnetic Roll Separator

- Magnetic Drum Separator

- Overband Magnetic Separator

- Top Pipeline Magnet Products

- Gyro Screen Machine

- Vibro Screen

- Magnetic roll separator magnetic destoner

- Magnetic Drum Separator

- High Power Magnetic Rod

- Industrial Suspension Magnet

- Hopper Magnetic Grill

- Plate Magnet

- Magnetic Rod Manufacturers

- Super Magnetic Plate Suppliers

- Super Magnetic Plate

- Magnetic Plates Exporters

- Magnetic Plates Manufacturers Andhra Pradesh

- Magnetic Rod Suppliers

- Magnetic Rod Company

- Magnetic Plate Manufacturer

- Strong Magnetic Rod

- Magnetic Plate

- Magnetic Rod Price Manufacturer

- Magnetic Rod

- Heavy Duty Industrial Magnets

- Suspended Magnets Dealer

- Suspension Magnet Supplier

- Suspension Magnet Manufacturer

- Suspension Magnetic Separator

- Suspension Permanent Magnets

- Industrial Magnetic Grill

- Grill Magnet Manufacturer Mizoram

- Magnetic Grill Manufacturer

- Hopper Magnetic Grill

- Power Magnetic Grill

- Magnetic Grill