Magnetic Roll Separator for Mineral Processing Gujarat

Magnetic Roll Separator for Mineral Processing Gujarat

Introduction

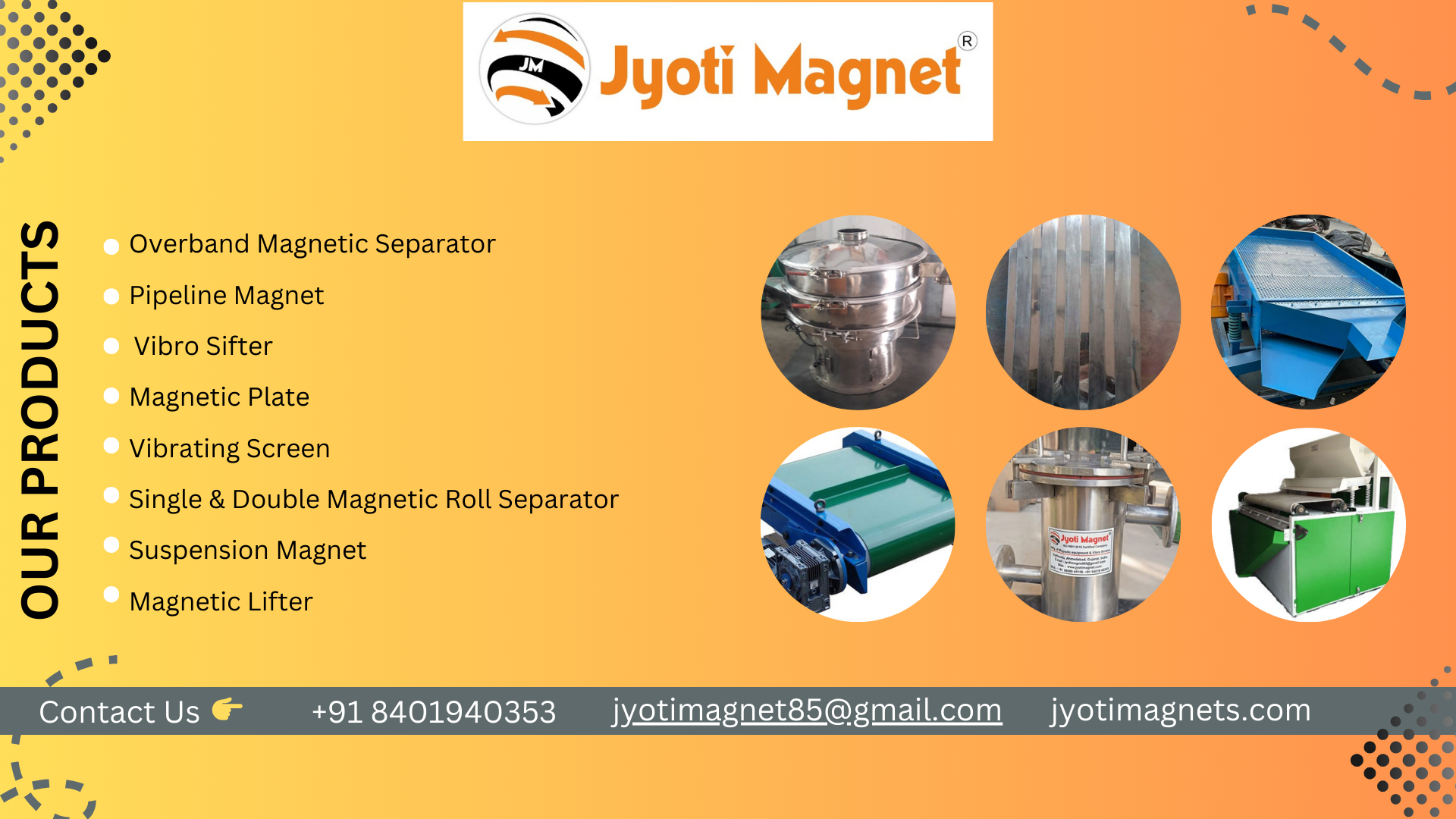

Jyoti Magnet offers high-intensity Magnetic Roll Separators designed specifically for mineral processing applications in Gujarat. These machines deliver efficient dry separation of ferrous and weakly magnetic minerals, enhancing product purity and operational efficiency.

What is Magnetic Roll Separator?

A Magnetic Roll Separator is a dry-type magnetic separator featuring rare earth magnetized rolls that attract and separate magnetic materials from non-magnetic feeds. Offered by Jyoti Magnet, it is ideal for fine to coarse mineral processing.

How Does It Work?

The separation process involves:

• Feeding mineral mixture onto the roll surface• High-intensity magnetism attracts magnetic particles

• Non-magnetic fractions fall away

• Splitters divide outlets

• Continuous operation without water

Applications / Where It’s Used

• Iron ore beneficiation• Tin and tungsten ore processing

• Quartz and feldspar purification

• Garnet & heavy mineral separation

• Pharmaceutical and ceramic feedstock

• Coal and lignite cleaning

• Silica sand beneficiation

• E-waste magnetic separation

Key Benefits of Magnetic Roll Separator

• High magnetic strength with rare earth rolls• Dry processing minimizes water usage

• Low maintenance & energy efficient

• Compact and modular design

• Improves downstream product quality

Technical Features & Specifications

• Rare earth Neodymium magnet rolls• Roll width 100 – 600 mm

• Speeds up to 60 m/min

• Adjustable splitters for separation

• Powder-coated steel body

• Mounted on skid for easy setup

• Designed by Jyoti Magnet

• CE & ISO compliant designs

Industry Standards & Compliance

• ISO 9001:2015 certified manufacturer• CE-marked products

• Built to GMP and safety standards

• Dust-proof and environment-friendly

• Quality tested as per industrial norms

Why Choose Jyoti Magnet?

• Over 30 years in magnetic separation• Custom solutions for mineral sector

• Field support and equipment trials

• Nationwide delivery & setup

• Competitive pricing and built quality

• Skilled R&D and production teams

• 1,000+ installations across India

• Strong service & spare backup

• Trusted by mineral processers in Gujarat

Comparison with Other Technologies

Compared to drum or wet separators:

• No water required for dry operations• Higher magnetic intensity and selectivity

• Simpler operation and maintenance

• Compact footprint suitable for small plants

• Better suited for fine particle processing

Frequently Asked Questions (FAQs)

1. What mineral types can it process?

Iron ore, garnet, silica, feldspar, and more can be processed efficiently.

2. What particle size range is handled?

Treats particles from 50 µm up to 3 mm.

3. What roll widths are available?

Rolls range from 100 mm to 600 mm depending on model.

4. Is trial on customer material available?

Yes, Jyoti Magnet offers lab and site trials.

5. Is it suitable for wet environments?

Designed for dry operation but water-resistant versions are available.

6. What power is required?

Standard 220 V / 380 V three-phase electrical supply.

7. Can the roll speed be adjusted?

Yes, RPM is adjustable to match material flow.

8. What is the maintenance frequency?

Typically requires annual inspection and coil checking.

9. Does it come with warranty?

Standard 12-month warranty on parts and performance.

10. Are replacement magnets available?

Yes, spare rolls and magnets are stocked by Jyoti Magnet.

Conclusion & Final Thoughts

For mineral processing in Gujarat, a Magnetic Roll Separator from Jyoti Magnet delivers unmatched performance, efficiency, and reliability. Perfect for enhancing productivity and product quality in your plant.

Contact / Inquiry Information

Contact: +91 8401940353

Email: jyotimagnet85@gmail.com

Website: https://jyotimagnets.com

Facebook: Jyoti Magnet Facebook

LinkedIn: Jyoti Magnet LinkedIn

YouTube: Jyoti Magnet YouTube

Instagram: Jyoti Magnet Instagram

Filter Using Tags

Our Blogs

- Magnetic Destoner Exporter from Ahmedabad

- Trusted Magnetic Roll Separator Manufacturer in India

- Leading Magnetic Destoner Supplier in Gujarat

- Best Magnetic Roll Separator Manufacturer in Ahmedabad

- Magnetic Destoner Machine Supplier Gujarat

- Magnetic Destoner for Grain Cleaning Ahmedabad

- Industrial Magnetic Destoner Manufacturer in India

- Magnetic Destoner Supplier in Gujarat

- Magnetic Destoner Manufacturer in Ahmedabad

- Magnetic Roll Separator for Mineral Processing Gujarat

- Rare Earth Magnetic Roll Separator Manufacturer Ahmedabad

- High-Intensity Magnetic Roll Separator Manufacturer in India

- Magnetic Roll Separator Supplier in Gujarat

- Magnetic Roll Separator Manufacturer in Ahmedabad

- Top Magnetic Separator Drum Manufacturer in Gujarat

- Magnetic Drum Separator Exporter from Ahmedabad

- Trusted Magnetic Drum Separator Manufacturer in India

- Leading Magnetic Drum Separator Supplier in Gujarat

- Best Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Manufacturer in Gujarat

- Heavy Duty Magnetic Drum Separator Supplier Ahmedabad

- Magnetic Drum Separator Machine Manufacturer India

- Industrial Magnetic Drum Separator Supplier Gujarat

- Magnetic Separator Drum Manufacturer Ahmedabad

- Automatic Magnetic Drum Separator Manufacturer in India

- Magnetic Drum Separator Supplier in Gujarat

- Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Equipment Supplier

- Best Magnetic Separator Manufacturer in China

- Magnetic Roller Separator Exporter from India

- Magnetic Roll Separator Manufacturer in Gujarat

- Rare Earth Magnetic Separator

- High Intensity Magnetic Separator Supplier

- Magnetic Roll Separator

- Magnetic Roller Separator Machine?

- High Intensity Magnetic Separator Manufacturer

- Magnetic Roll Separator Manufacturer

- Dry Magnetic Separator

- High Intensity Magnetic Separator

- Magnetic Roller Separator

- Magnetic Rods Price

- Top Magnetic Rod Manufacturers

- Vibro Sifter Machine Exporter in Gujarat

- Industrial Vibro Destoner Machine

- Vibro Destoner Machine

- Automatic Vibro Destoner Machine in Ahmedabad

- Magnetic Destoner Machine Manufacturer

- Automatic Magnetic Destoner

- Hopper Magnet Manufacturer in Ahmedabad

- Magnetic Destoner Machine

- Magnetic Destoner Rod

- Magnetic Destoner Manufacturers

- Magnetic Destoner Price & Overview

- Magnetic Destoner Manufacturers Near Me

- Magnetic Destoner Manufacturers in Ahmedabad

- Magnetic Destoner Manufacturers in India

- Magnetic Destoner Manufacturer

- Leading Industrial Magnetic Equipment Manufacturer in Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Efficient Vibro Sieves Manufacturer in India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Durable Drum Pulleys Exporter from Ahmedabad

- Reliable Suspension Magnet Manufacturer in India

- High-Quality Gyro Screen Machines Supplier in Gujarat

- Magnetic Separator for Industrial Use in Ahmedabad

- Magnetic Plate and Rod Supplier in Ahmedabad

- Suspension Magnet Exporter From Ahmedabad

- Gyro Screen Machine Supplier in Gujarat

- Magnetic Equipment Manufacturer in Ahmedabad

- Magnetic Rod Supplier in Ahmedabad

- Magnetic Bar Manufacturer in India

- Industrial Magnetic Equipment Manufacturer � Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Vibro Sieve Manufacturer India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Vibro Sifter Manufacturer

- Gyro Screen Machine

- Vibro Sieve

- Vibro Screen

- Magnetic Grill

- Magnetic Tube

- Magnetic Bar

- Magnetic Rod

- Magnetic Destoner

- Magnetic Roll Separator

- Magnetic Drum Separator

- Overband Magnetic Separator

- Top Pipeline Magnet Products

- Gyro Screen Machine

- Vibro Screen

- Magnetic roll separator magnetic destoner

- Magnetic Drum Separator

- High Power Magnetic Rod

- Industrial Suspension Magnet

- Hopper Magnetic Grill

- Plate Magnet

- Magnetic Rod Manufacturers

- Super Magnetic Plate Suppliers

- Super Magnetic Plate

- Magnetic Plates Exporters

- Magnetic Plates Manufacturers Andhra Pradesh

- Magnetic Rod Suppliers

- Magnetic Rod Company

- Magnetic Plate Manufacturer

- Strong Magnetic Rod

- Magnetic Plate

- Magnetic Rod Price Manufacturer

- Magnetic Rod

- Heavy Duty Industrial Magnets

- Suspended Magnets Dealer

- Suspension Magnet Supplier

- Suspension Magnet Manufacturer

- Suspension Magnetic Separator

- Suspension Permanent Magnets

- Industrial Magnetic Grill

- Grill Magnet Manufacturer Mizoram

- Magnetic Grill Manufacturer

- Hopper Magnetic Grill

- Power Magnetic Grill

- Magnetic Grill