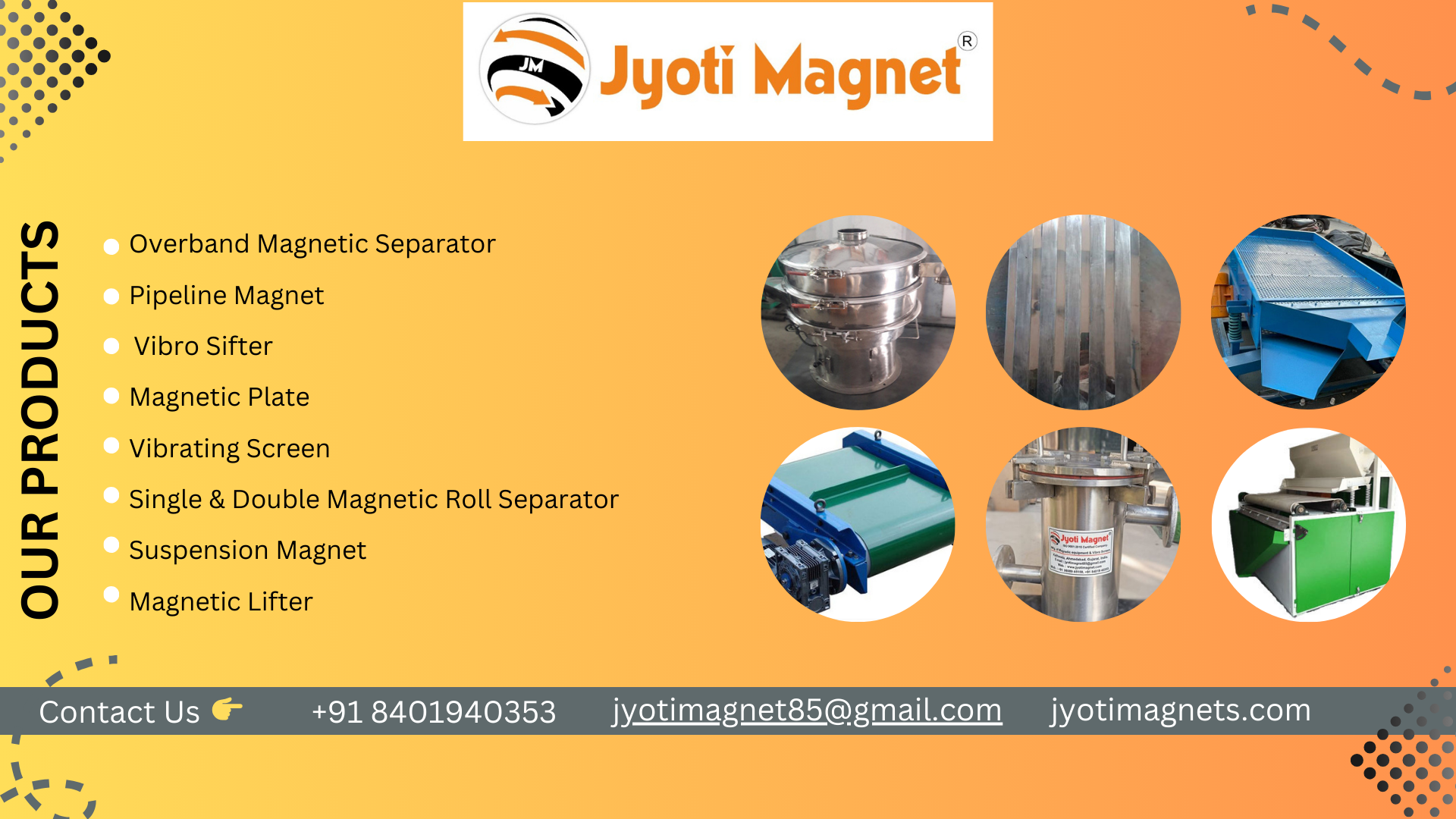

Vibro Sifter Machine Exporter in Gujarat

Vibro

Sifter Machine Exporter in Gujarat

A Vibro Sifter Machine (also called a vibrating

sifter or gyro screen) is a high-performance, circular vibrating screening

device used to separate and grade materials based on particle size. It utilizes

vibratory motor-induced gyratory motion to efficiently sieve powders,

granules, and liquids across multiple mesh layers.

Designed for precision, cleanliness, and efficiency, the VibroSifter is widely used in pharmaceutical, food, chemical, and cosmetic

industries. Gujarat, known for its industrial excellence, is home to

several top-tier Vibro Sifter Machine exporters who supply robust and

GMP-compliant sifters to international markets.

Applications

- Pharmaceutical

Industry – Granule sieving, API separation, tablet dusting.

- Food

& Beverages – Flour, spices, sugar, milk powder, tea dust

filtration.

- Chemical

Industry – Classification of chemicals, resins, and plastics.

- Cosmetic

Industry – Sieving of powders, talc, and raw materials.

- Paints

& Pigments – Filtration of paints and colorants.

- Ceramics

& Minerals – Clay, silica, dolomite, feldspar classification.

- Agro

& Fertilizers – Urea, NPK, and granule sorting.

- Recycling

Plants – Separation of plastic chips and scrap granules.

10

Frequently Asked Questions (FAQs)

- Q:

What is a Vibro Sifter used for?

A: For separating, grading, and filtering dry powders, granules, and liquid slurries by particle size. - Q:

How many decks can it have?

A: Typically 1 to 4 decks (sieves), depending on separation requirement. - Q:

What materials is it made from?

A: Usually SS304 or SS316L stainless steel for contact parts (GMP compliant). - Q:

Is it suitable for wet and dry materials?

A: Yes, it can handle both wet slurry and dry powder separation. - Q:

What mesh sizes are available?

A: From 4 mesh (coarse) up to 500 mesh (fine); customized as per application. - Q:

Can it be used for continuous operation?

A: Yes, designed for 24x7 industrial usage with minimal maintenance. - Q:

Does it comply with GMP standards?

A: Yes, especially models built for the pharmaceutical and food sectors. - Q:

What is the power consumption?

A: Depends on model size – usually between 0.25 HP to 3 HP motors. - Q:

Can it be customized?

A: Yes, exporters in Gujarat often offer customized sizes, mesh configurations, and feeding systems. - Q:

Is it noisy or vibrationally disturbing?

A: Low-noise operation with rubber mountings to absorb vibration.

Features

and Their Practical Uses

|

Feature |

Use / Benefit |

|

Gyratory Vibration Motor |

|

Multi-Deck Design |

Enables multi-stage separation or grading in one cycle. |

|

Quick Clamp Assembly |

Allows fast screen changeover and cleaning – essential for

hygiene. |

|

SS304/SS316L Construction |

Corrosion-resistant and suitable for food/pharma use. |

|

Mirror/Mat Finish Options |

Mirror polish for pharma-grade; matt finish for industrial

use. |

|

Compact & Modular Design |

Fits easily in production lines with limited space. |

|

Anti-Vibration Rubber Mounts |

Reduces noise, vibration transmission to floor, and wear. |

|

Custom Mesh Screens |

Achieve precise particle separation for specific industry

standards. |

|

Dust-Free Sealed Unit |

Ensures no contamination or product loss during screening. |

|

Energy Efficient Motor |

Reduces power usage while maintaining consistent output. |

Key

Points

- Manufacturing

Base: Gujarat is a hub for industrial machinery, offering globally competitive rates and quality.

- Material

Quality: Use of premium-grade SS304/316 ensures global export

compliance (EU/FDA/GMP).

- Customization:

Mesh size, deck count, feeding, and discharge systems can be tailored for

client needs.

- Export

Markets: Widely exported to Africa, Middle East, Southeast Asia,

Europe, and Latin America.

- Compliance:

CE-certified, ISO-compliant machines available for international markets.

- Capacity

Range: From small lab models (12” diameter) to large industrial models

(up to 72”).

- Availability:

Ready stock for standard models and fast delivery timelines.

- After-Sales

Service: Many exporters provide remote installation guidance and spare

part kits.

- Documentation:

Complete export documentation (COO, test certificates, user manual)

provided.

- Integration

Support: Machines can be integrated with conveyors, vacuum loaders,

and feeders.

Contact

Us For More Details On :

Call - +91 84019 40353

Facebook - www.facebook.com/JyotiMagnet

Instagram - www.instagram.com/jyotimagnet_india

YouTube - www.youtube.com/@jyotimagnet1587

Website – www.jyotimagnets.com

Email - jyotimagnet85@gmail.com

Filter Using Tags

Our Blogs

- Magnetic Destoner Exporter from Ahmedabad

- Trusted Magnetic Roll Separator Manufacturer in India

- Leading Magnetic Destoner Supplier in Gujarat

- Best Magnetic Roll Separator Manufacturer in Ahmedabad

- Magnetic Destoner Machine Supplier Gujarat

- Magnetic Destoner for Grain Cleaning Ahmedabad

- Industrial Magnetic Destoner Manufacturer in India

- Magnetic Destoner Supplier in Gujarat

- Magnetic Destoner Manufacturer in Ahmedabad

- Magnetic Roll Separator for Mineral Processing Gujarat

- Rare Earth Magnetic Roll Separator Manufacturer Ahmedabad

- High-Intensity Magnetic Roll Separator Manufacturer in India

- Magnetic Roll Separator Supplier in Gujarat

- Magnetic Roll Separator Manufacturer in Ahmedabad

- Top Magnetic Separator Drum Manufacturer in Gujarat

- Magnetic Drum Separator Exporter from Ahmedabad

- Trusted Magnetic Drum Separator Manufacturer in India

- Leading Magnetic Drum Separator Supplier in Gujarat

- Best Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Manufacturer in Gujarat

- Heavy Duty Magnetic Drum Separator Supplier Ahmedabad

- Magnetic Drum Separator Machine Manufacturer India

- Industrial Magnetic Drum Separator Supplier Gujarat

- Magnetic Separator Drum Manufacturer Ahmedabad

- Automatic Magnetic Drum Separator Manufacturer in India

- Magnetic Drum Separator Supplier in Gujarat

- Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Equipment Supplier

- Best Magnetic Separator Manufacturer in China

- Magnetic Roller Separator Exporter from India

- Magnetic Roll Separator Manufacturer in Gujarat

- Rare Earth Magnetic Separator

- High Intensity Magnetic Separator Supplier

- Magnetic Roll Separator

- Magnetic Roller Separator Machine?

- High Intensity Magnetic Separator Manufacturer

- Magnetic Roll Separator Manufacturer

- Dry Magnetic Separator

- High Intensity Magnetic Separator

- Magnetic Roller Separator

- Magnetic Rods Price

- Top Magnetic Rod Manufacturers

- Vibro Sifter Machine Exporter in Gujarat

- Industrial Vibro Destoner Machine

- Vibro Destoner Machine

- Automatic Vibro Destoner Machine in Ahmedabad

- Magnetic Destoner Machine Manufacturer

- Automatic Magnetic Destoner

- Hopper Magnet Manufacturer in Ahmedabad

- Magnetic Destoner Machine

- Magnetic Destoner Rod

- Magnetic Destoner Manufacturers

- Magnetic Destoner Price & Overview

- Magnetic Destoner Manufacturers Near Me

- Magnetic Destoner Manufacturers in Ahmedabad

- Magnetic Destoner Manufacturers in India

- Magnetic Destoner Manufacturer

- Leading Industrial Magnetic Equipment Manufacturer in Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Efficient Vibro Sieves Manufacturer in India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Durable Drum Pulleys Exporter from Ahmedabad

- Reliable Suspension Magnet Manufacturer in India

- High-Quality Gyro Screen Machines Supplier in Gujarat

- Magnetic Separator for Industrial Use in Ahmedabad

- Magnetic Plate and Rod Supplier in Ahmedabad

- Suspension Magnet Exporter From Ahmedabad

- Gyro Screen Machine Supplier in Gujarat

- Magnetic Equipment Manufacturer in Ahmedabad

- Magnetic Rod Supplier in Ahmedabad

- Magnetic Bar Manufacturer in India

- Industrial Magnetic Equipment Manufacturer – Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Vibro Sieve Manufacturer India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Vibro Sifter Manufacturer

- Gyro Screen Machine

- Vibro Sieve

- Vibro Screen

- Magnetic Grill

- Magnetic Tube

- Magnetic Bar

- Magnetic Rod

- Magnetic Destoner

- Magnetic Roll Separator

- Magnetic Drum Separator

- Overband Magnetic Separator

- Top Pipeline Magnet Products

- Gyro Screen Machine

- Vibro Screen

- Magnetic roll separator magnetic destoner

- Magnetic Drum Separator

- High Power Magnetic Rod

- Industrial Suspension Magnet

- Hopper Magnetic Grill

- Plate Magnet

- Magnetic Rod Manufacturers

- Super Magnetic Plate Suppliers

- Super Magnetic Plate

- Magnetic Plates Exporters

- Magnetic Plates Manufacturers Andhra Pradesh

- Magnetic Rod Suppliers

- Magnetic Rod Company

- Magnetic Plate Manufacturer

- Strong Magnetic Rod

- Magnetic Plate

- Magnetic Rod Price Manufacturer

- Magnetic Rod

- Heavy Duty Industrial Magnets

- Suspended Magnets Dealer

- Suspension Magnet Supplier

- Suspension Magnet Manufacturer

- Suspension Magnetic Separator

- Suspension Permanent Magnets

- Industrial Magnetic Grill

- Grill Magnet Manufacturer Mizoram

- Magnetic Grill Manufacturer

- Hopper Magnetic Grill

- Power Magnetic Grill

- Magnetic Grill