Magnetic Roll Separator Manufacturer in Ahmedabad

Magnetic Roll Separator Manufacturer in Ahmedabad

Introduction

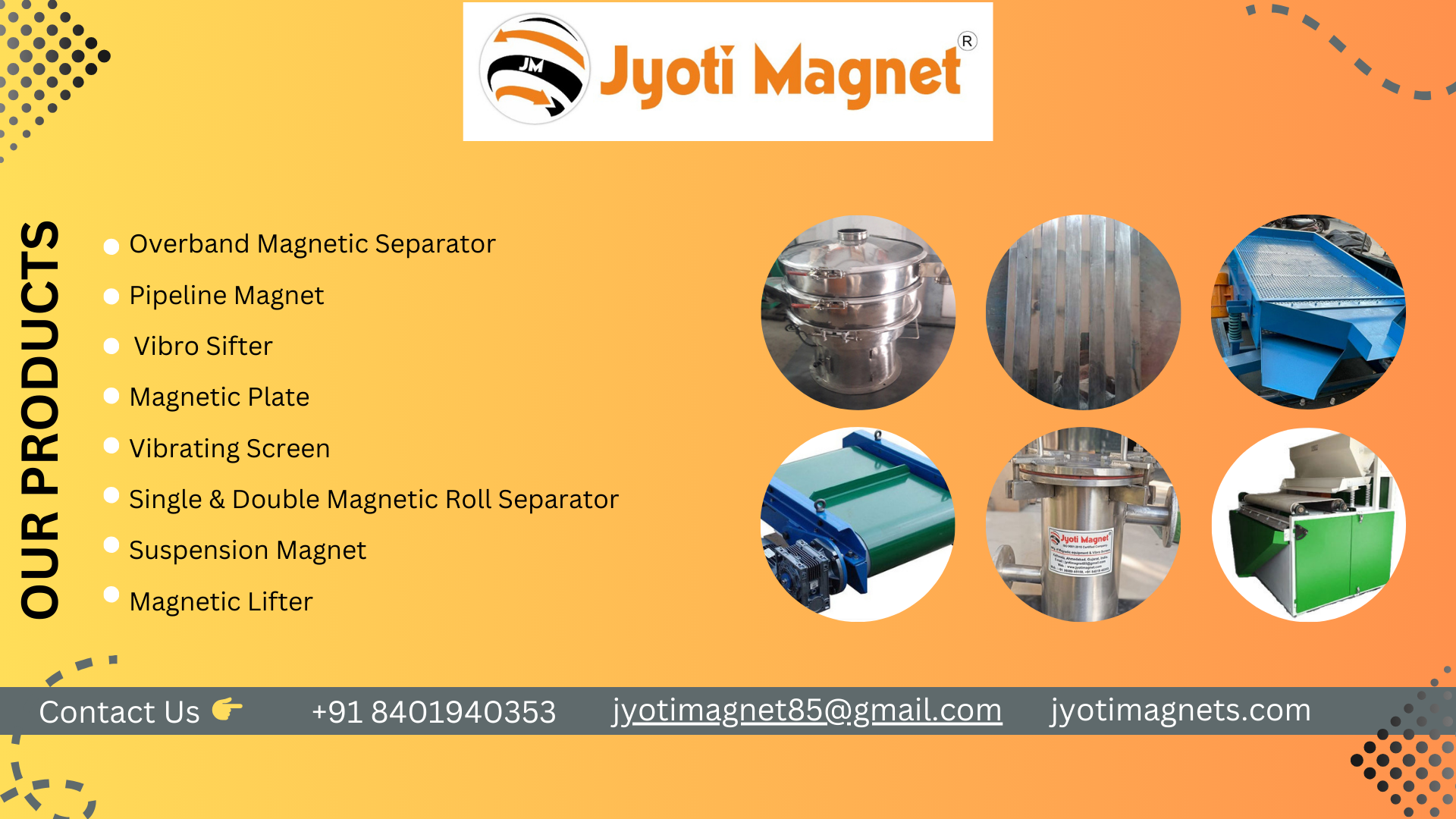

Jyoti Magnets is a leading Magnetic Roll Separator manufacturer in Ahmedabad, offering robust and efficient separation solutions for various industries. Our equipment ensures optimal metal removal and purity in process streams.

What is Magnetic Roll Separator?

A Magnetic Roll Separator is a device using rotating magnetic discs to extract fine and weakly magnetic particles from materials. Jyoti’s separators are designed for coal, minerals, food, and petrochemical industries in Ahmedabad and beyond.

How Does It Work?

The system functions by:

• Material feeding over a rotating drum with magnetic poles underneath• Ferrous particles adhere to drum surface

• BPM (backpole magnets) pull off collected particles into discharge chute

• Non-magnetic waste continues downstream

This ensures effective separation of fine ferrous contaminants.

Applications / Where It’s Used

• Coal handling plants• Mineral processing units

• Ceramic and glass industries

• Chemical feedstock cleaning

• Plastic recycling

• Food and grain processing

• Petrochemical raw materials

• Ahmedabad industrial facilities

Key Benefits of Magnetic Roll Separator

• High separation efficiency• Removes fine weakly magnetic particles

• Maintenance-free permanent magnets

• Durable construction for industrial conditions

• Energy-efficient rotating drum operation

• Customized drum sizes and configurations

• Hygienic design for food sector

• Ahmedabad-based service & support

• Precision-engineered by Jyoti Magnets

• Cost-effective metal removal

Technical Features & Specifications

• Magnetic strength up to 14,000 Gauss• Drum dia: 300–1200 mm

• Material of construction: Mild steel/SS

• Shaft-mounted permanent magnet assemblies

• RPM: adjustable 5–60 rpm

• IP55-rated motor and gearbox

• Discharge chutes & housing options

• Customizable pole pitch and coverage

• Industrial-grade bearings

• Designed by Jyoti Magnets

Industry Standards & Compliance

• ISO 9001 manufacturing• CE certified electricals

• Material contact safe for food grade

• Industry-standard testing protocols

• Lloyds and third-party inspection available

• Compliant with industrial safety norms

Why Choose Jyoti Magnets?

• Expert magnetic separation manufacturer• Customized solutions per client need

• Quick delivery from Ahmedabad plant

• Strong after-sales service network

• R&D-backed equipment design

• Competitive pricing for quality builds

• On-site commissioning & training

• Trusted by Indian industries

• Visit Jyoti Magnets for detailed catalogs

• Local support in Ahmedabad region

Comparison with Other Technologies

Magnetic Roll Separator vs Magnetic Grate or Plate Separators:

• More effective for fine and weak particles• Continuous self-cleaning drum

• Less pressure drop in material flow

• Compact and easy to integrate

• Suitable for both wet and dry applications

Frequently Asked Questions (FAQs)

1. What particle size can be separated?

Designed to remove particles down to 30 microns depending on magnet strength.

2. Can it handle wet materials?

Yes, models are available for wet and slurry feed applications.

3. What maintenance is required?

Minimal—just periodic drum inspection and cleaning of housing.

4. Are customized drum sizes offered?

Yes, we design drums from 300 mm up to 1200 mm diameter to match process needs.

5. What is the standard magnetic strength?

Up to 14,000 Gauss using high-grade NdFeB permanent magnets.

6. Is electrical supply needed?

Yes, 415 V three-phase motor drive is standard; single-phase on request.

7. Are spares available locally?

Yes, spare drum covers, bearings, and magnets are stocked in Ahmedabad.

8. Can it be retrofitted into existing systems?

Absolutely—we offer mounting and integration support to fit your layout.

9. Is operator training provided?

Yes, full training is provided by our technical team on-site in Ahmedabad.

10. How can I request a quote?

Contact us below or visit our website to submit specifications.

Conclusion & Final Thoughts

Jyoti’s Magnetic Roll Separator offers a reliable, efficient, and compact solution for metal removal in industrial processes. Designed and supported from Ahmedabad, it ensures purity and process improvements across industries.

Contact / Inquiry Information

Contact: +91 8401940353

Email: jyotimagnet85@gmail.com

Website: https://jyotimagnets.com/

Filter Using Tags

Our Blogs

- Magnetic Destoner Exporter from Ahmedabad

- Trusted Magnetic Roll Separator Manufacturer in India

- Leading Magnetic Destoner Supplier in Gujarat

- Best Magnetic Roll Separator Manufacturer in Ahmedabad

- Magnetic Destoner Machine Supplier Gujarat

- Magnetic Destoner for Grain Cleaning Ahmedabad

- Industrial Magnetic Destoner Manufacturer in India

- Magnetic Destoner Supplier in Gujarat

- Magnetic Destoner Manufacturer in Ahmedabad

- Magnetic Roll Separator for Mineral Processing Gujarat

- Rare Earth Magnetic Roll Separator Manufacturer Ahmedabad

- High-Intensity Magnetic Roll Separator Manufacturer in India

- Magnetic Roll Separator Supplier in Gujarat

- Magnetic Roll Separator Manufacturer in Ahmedabad

- Top Magnetic Separator Drum Manufacturer in Gujarat

- Magnetic Drum Separator Exporter from Ahmedabad

- Trusted Magnetic Drum Separator Manufacturer in India

- Leading Magnetic Drum Separator Supplier in Gujarat

- Best Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Manufacturer in Gujarat

- Heavy Duty Magnetic Drum Separator Supplier Ahmedabad

- Magnetic Drum Separator Machine Manufacturer India

- Industrial Magnetic Drum Separator Supplier Gujarat

- Magnetic Separator Drum Manufacturer Ahmedabad

- Automatic Magnetic Drum Separator Manufacturer in India

- Magnetic Drum Separator Supplier in Gujarat

- Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Equipment Supplier

- Best Magnetic Separator Manufacturer in China

- Magnetic Roller Separator Exporter from India

- Magnetic Roll Separator Manufacturer in Gujarat

- Rare Earth Magnetic Separator

- High Intensity Magnetic Separator Supplier

- Magnetic Roll Separator

- Magnetic Roller Separator Machine?

- High Intensity Magnetic Separator Manufacturer

- Magnetic Roll Separator Manufacturer

- Dry Magnetic Separator

- High Intensity Magnetic Separator

- Magnetic Roller Separator

- Magnetic Rods Price

- Top Magnetic Rod Manufacturers

- Vibro Sifter Machine Exporter in Gujarat

- Industrial Vibro Destoner Machine

- Vibro Destoner Machine

- Automatic Vibro Destoner Machine in Ahmedabad

- Magnetic Destoner Machine Manufacturer

- Automatic Magnetic Destoner

- Hopper Magnet Manufacturer in Ahmedabad

- Magnetic Destoner Machine

- Magnetic Destoner Rod

- Magnetic Destoner Manufacturers

- Magnetic Destoner Price & Overview

- Magnetic Destoner Manufacturers Near Me

- Magnetic Destoner Manufacturers in Ahmedabad

- Magnetic Destoner Manufacturers in India

- Magnetic Destoner Manufacturer

- Leading Industrial Magnetic Equipment Manufacturer in Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Efficient Vibro Sieves Manufacturer in India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Durable Drum Pulleys Exporter from Ahmedabad

- Reliable Suspension Magnet Manufacturer in India

- High-Quality Gyro Screen Machines Supplier in Gujarat

- Magnetic Separator for Industrial Use in Ahmedabad

- Magnetic Plate and Rod Supplier in Ahmedabad

- Suspension Magnet Exporter From Ahmedabad

- Gyro Screen Machine Supplier in Gujarat

- Magnetic Equipment Manufacturer in Ahmedabad

- Magnetic Rod Supplier in Ahmedabad

- Magnetic Bar Manufacturer in India

- Industrial Magnetic Equipment Manufacturer � Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Vibro Sieve Manufacturer India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Vibro Sifter Manufacturer

- Gyro Screen Machine

- Vibro Sieve

- Vibro Screen

- Magnetic Grill

- Magnetic Tube

- Magnetic Bar

- Magnetic Rod

- Magnetic Destoner

- Magnetic Roll Separator

- Magnetic Drum Separator

- Overband Magnetic Separator

- Top Pipeline Magnet Products

- Gyro Screen Machine

- Vibro Screen

- Magnetic roll separator magnetic destoner

- Magnetic Drum Separator

- High Power Magnetic Rod

- Industrial Suspension Magnet

- Hopper Magnetic Grill

- Plate Magnet

- Magnetic Rod Manufacturers

- Super Magnetic Plate Suppliers

- Super Magnetic Plate

- Magnetic Plates Exporters

- Magnetic Plates Manufacturers Andhra Pradesh

- Magnetic Rod Suppliers

- Magnetic Rod Company

- Magnetic Plate Manufacturer

- Strong Magnetic Rod

- Magnetic Plate

- Magnetic Rod Price Manufacturer

- Magnetic Rod

- Heavy Duty Industrial Magnets

- Suspended Magnets Dealer

- Suspension Magnet Supplier

- Suspension Magnet Manufacturer

- Suspension Magnetic Separator

- Suspension Permanent Magnets

- Industrial Magnetic Grill

- Grill Magnet Manufacturer Mizoram

- Magnetic Grill Manufacturer

- Hopper Magnetic Grill

- Power Magnetic Grill

- Magnetic Grill