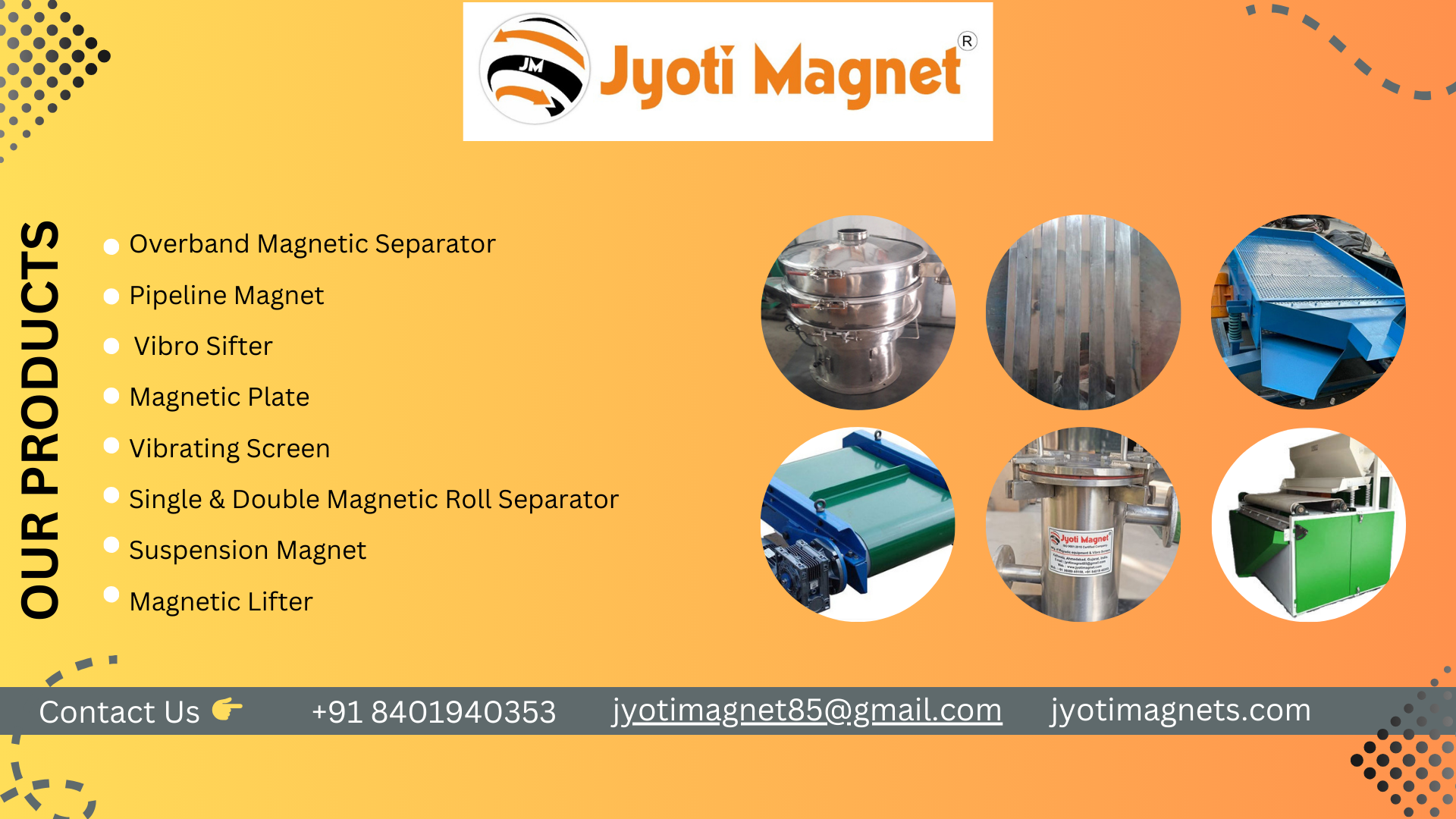

High Intensity Magnetic Separator Manufacturer

High

Intensity Magnetic Separator Manufacturer

A High Intensity Magnetic Separator Manufacturer specializes

in producing advanced separation systems designed to remove ferrous and

paramagnetic contaminants from dry, granular, or powdery materials. These

machines are widely used in mining, ceramics, food, plastics, and recycling

industries for precision separation and purification. The manufacturers offer

both standard and custom-built models to match specific application needs. With

high magnetic strength and energy-efficient designs, they ensure superior

separation performance and consistent product quality.

10

Frequently Asked Questions (FAQs)

- What

is a High Intensity Magnetic Separator?

It's a machine that uses strong magnetic fields to separate magnetic and weakly magnetic particles from non-magnetic materials. - What

industries use these separators?

Mining, ceramics, food processing, pharmaceuticals, plastics, chemicals, and recycling. - What

types of materials can be processed?

Minerals (like quartz, feldspar), powders, fine ores, plastics, food ingredients, etc. - What

is the magnetic field strength?

High-intensity separators can reach up to 20,000 Gauss, depending on design. - Is

it suitable for dry or wet materials?

Both types are available—dry and wet high-intensity magnetic separators. - Can

it remove weakly magnetic materials like hematite?

Yes, high-intensity separators are capable of separating weakly magnetic materials. - Do

manufacturers offer customization?

Yes, many provide tailor-made solutions based on material type and throughput. - Is

regular maintenance required?

Minimal, but routine inspection and cleaning are recommended for optimal performance. - Are

safety features included?

Yes, models come with safety interlocks, overload protection, and easy access for cleaning. - Can

it be integrated into automated systems?

Absolutely, most modern units are PLC compatible and ready for integration.

Applications

- Mining

& Minerals: Separation of iron and rare earth minerals

- Ceramics:

Removal of iron from quartz and feldspar

- Food

Industry: Removing ferrous contaminants from spices and grains

- Plastic

& Recycling: Purifying shredded plastic or rubber

- Pharmaceuticals:

Ensuring contaminant-free powder processing

- Chemical

Industry: Purification of catalysts, pigments, and powders

Features

- High Gauss intensity (up to 20,000 Gauss or more)

- Neodymium

rare-earth magnets for strong performance

- Stainless

steel construction (304/316 grade)

- Adjustable

magnetic field and speed settings

- Compact

and modular design

- Low

power consumption with high efficiency

- Easy

cleaning and maintenance

- Available

in roller, drum, and plate designs

Uses

- Iron removal from raw materials

- Enhancing

purity of non-metallic minerals

- Recovering

valuable magnetic materials

- Protecting

downstream equipment from metal damage

- Increasing

product quality in sensitive processing industries

Handling

Instructions

- Ensure power is off before cleaning or inspection

- Regularly

check the magnetic surface for buildup

- Avoid

mechanical shocks to magnetic components

- Use

proper PPE when handling strong magnets

- Maintain

proper feeding rate to ensure separation efficiency

Benefits

- High separation efficiency even for fine and weakly magnetic particles

- Increases

product purity and quality

- Protects

machinery from damage due to metal contaminants

- Reduces

production downtime

- Eco-friendly

operation with no chemical usage

- Long

service life with minimal maintenance

Key

Points

- Essential in industries where purity and contamination control are critical

- Available

in both dry and wet variants

- Customizable

to match throughput and material type

- Manufactured

using high-grade magnetic materials

- Trusted

by industries that rely on high precision separation

Conclusion

A High Intensity Magnetic Separator Manufacturer

delivers advanced separation solutions that are vital for improving material

purity, operational safety, and process efficiency across various industries.

Their expertise in magnet technology and commitment to quality ensures machines

that are robust, energy-efficient, and application-specific. Partnering with a

reputable manufacturer guarantees optimal performance, long-term reliability,

and technical support tailored to your separation needs.

Contact

Us For More Details On :

Call - +91 84019 40353

Facebook - www.facebook.com/JyotiMagnet

Instagram - www.instagram.com/jyotimagnet_india

YouTube - www.youtube.com/@jyotimagnet1587

Website – www.jyotimagnets.com

Email - jyotimagnet85@gmail.com

Filter Using Tags

Our Blogs

- Magnetic Destoner Exporter from Ahmedabad

- Trusted Magnetic Roll Separator Manufacturer in India

- Leading Magnetic Destoner Supplier in Gujarat

- Best Magnetic Roll Separator Manufacturer in Ahmedabad

- Magnetic Destoner Machine Supplier Gujarat

- Magnetic Destoner for Grain Cleaning Ahmedabad

- Industrial Magnetic Destoner Manufacturer in India

- Magnetic Destoner Supplier in Gujarat

- Magnetic Destoner Manufacturer in Ahmedabad

- Magnetic Roll Separator for Mineral Processing Gujarat

- Rare Earth Magnetic Roll Separator Manufacturer Ahmedabad

- High-Intensity Magnetic Roll Separator Manufacturer in India

- Magnetic Roll Separator Supplier in Gujarat

- Magnetic Roll Separator Manufacturer in Ahmedabad

- Top Magnetic Separator Drum Manufacturer in Gujarat

- Magnetic Drum Separator Exporter from Ahmedabad

- Trusted Magnetic Drum Separator Manufacturer in India

- Leading Magnetic Drum Separator Supplier in Gujarat

- Best Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Manufacturer in Gujarat

- Heavy Duty Magnetic Drum Separator Supplier Ahmedabad

- Magnetic Drum Separator Machine Manufacturer India

- Industrial Magnetic Drum Separator Supplier Gujarat

- Magnetic Separator Drum Manufacturer Ahmedabad

- Automatic Magnetic Drum Separator Manufacturer in India

- Magnetic Drum Separator Supplier in Gujarat

- Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Equipment Supplier

- Best Magnetic Separator Manufacturer in China

- Magnetic Roller Separator Exporter from India

- Magnetic Roll Separator Manufacturer in Gujarat

- Rare Earth Magnetic Separator

- High Intensity Magnetic Separator Supplier

- Magnetic Roll Separator

- Magnetic Roller Separator Machine?

- High Intensity Magnetic Separator Manufacturer

- Magnetic Roll Separator Manufacturer

- Dry Magnetic Separator

- High Intensity Magnetic Separator

- Magnetic Roller Separator

- Magnetic Rods Price

- Top Magnetic Rod Manufacturers

- Vibro Sifter Machine Exporter in Gujarat

- Industrial Vibro Destoner Machine

- Vibro Destoner Machine

- Automatic Vibro Destoner Machine in Ahmedabad

- Magnetic Destoner Machine Manufacturer

- Automatic Magnetic Destoner

- Hopper Magnet Manufacturer in Ahmedabad

- Magnetic Destoner Machine

- Magnetic Destoner Rod

- Magnetic Destoner Manufacturers

- Magnetic Destoner Price & Overview

- Magnetic Destoner Manufacturers Near Me

- Magnetic Destoner Manufacturers in Ahmedabad

- Magnetic Destoner Manufacturers in India

- Magnetic Destoner Manufacturer

- Leading Industrial Magnetic Equipment Manufacturer in Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Efficient Vibro Sieves Manufacturer in India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Durable Drum Pulleys Exporter from Ahmedabad

- Reliable Suspension Magnet Manufacturer in India

- High-Quality Gyro Screen Machines Supplier in Gujarat

- Magnetic Separator for Industrial Use in Ahmedabad

- Magnetic Plate and Rod Supplier in Ahmedabad

- Suspension Magnet Exporter From Ahmedabad

- Gyro Screen Machine Supplier in Gujarat

- Magnetic Equipment Manufacturer in Ahmedabad

- Magnetic Rod Supplier in Ahmedabad

- Magnetic Bar Manufacturer in India

- Industrial Magnetic Equipment Manufacturer – Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Vibro Sieve Manufacturer India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Vibro Sifter Manufacturer

- Gyro Screen Machine

- Vibro Sieve

- Vibro Screen

- Magnetic Grill

- Magnetic Tube

- Magnetic Bar

- Magnetic Rod

- Magnetic Destoner

- Magnetic Roll Separator

- Magnetic Drum Separator

- Overband Magnetic Separator

- Top Pipeline Magnet Products

- Gyro Screen Machine

- Vibro Screen

- Magnetic roll separator magnetic destoner

- Magnetic Drum Separator

- High Power Magnetic Rod

- Industrial Suspension Magnet

- Hopper Magnetic Grill

- Plate Magnet

- Magnetic Rod Manufacturers

- Super Magnetic Plate Suppliers

- Super Magnetic Plate

- Magnetic Plates Exporters

- Magnetic Plates Manufacturers Andhra Pradesh

- Magnetic Rod Suppliers

- Magnetic Rod Company

- Magnetic Plate Manufacturer

- Strong Magnetic Rod

- Magnetic Plate

- Magnetic Rod Price Manufacturer

- Magnetic Rod

- Heavy Duty Industrial Magnets

- Suspended Magnets Dealer

- Suspension Magnet Supplier

- Suspension Magnet Manufacturer

- Suspension Magnetic Separator

- Suspension Permanent Magnets

- Industrial Magnetic Grill

- Grill Magnet Manufacturer Mizoram

- Magnetic Grill Manufacturer

- Hopper Magnetic Grill

- Power Magnetic Grill

- Magnetic Grill