Magnetic Roller Separator Exporter from India

Magnetic Roller Separator Exporter from India

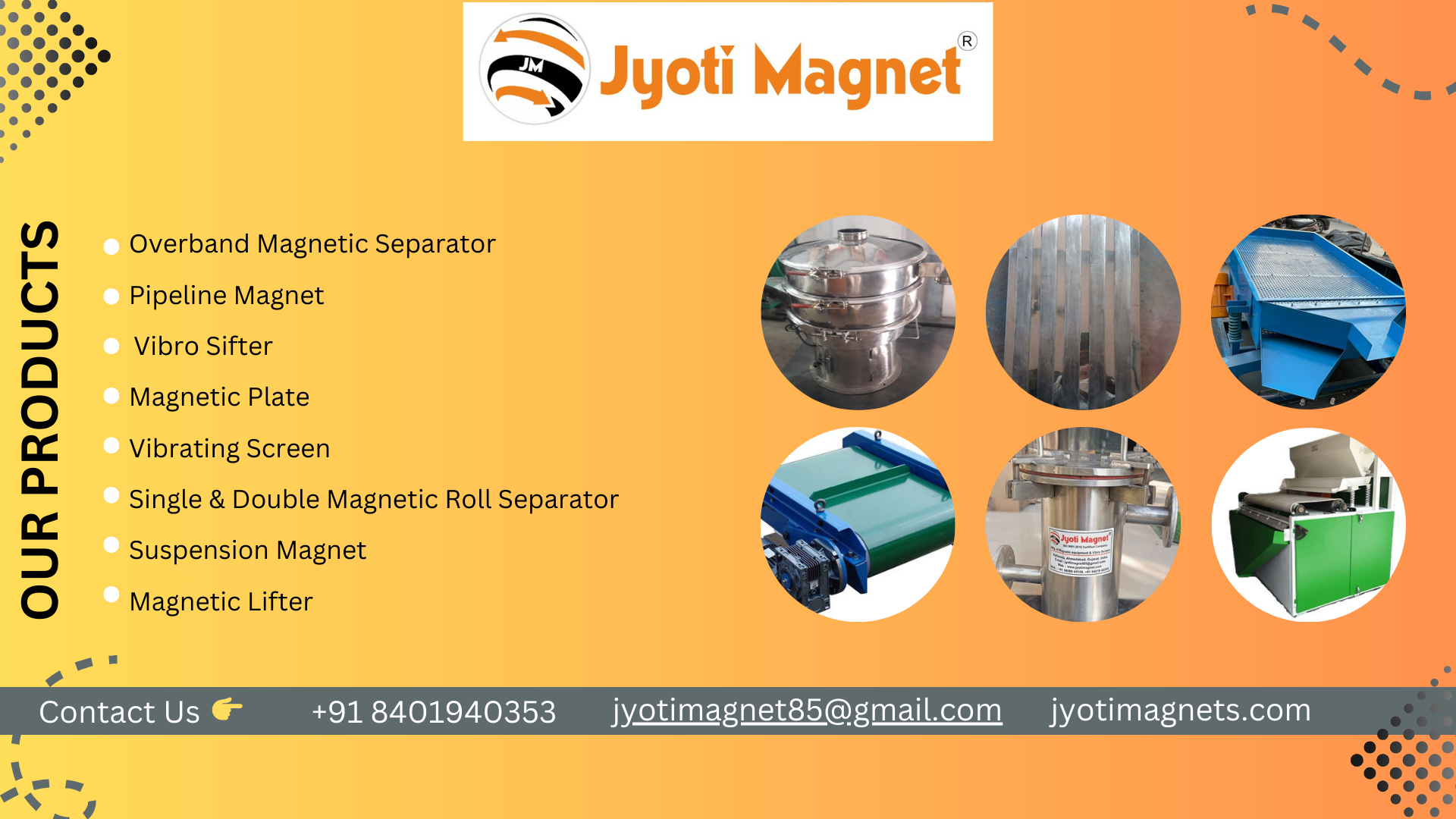

Description

A Magnetic Roller Separator (also called High-Intensity Magnetic Separator) is a specialized industrial equipment used to separate ferrous and paramagnetic impurities from non-magnetic materials such as minerals, plastics, chemicals, food grains, etc. It works using high-intensity rare earth magnets (NdFeB) fitted on rollers that attract and separate fine iron contaminants from dry material flow.

Indian exporters are known for offering custom-built, high-performance, and export-compliant magnetic roller separators that cater to both domestic and global industries.

How Itís Made

The manufacturing process involves:

-

Design Engineering:

-

CAD modeling based on capacity (TPH), material type, and particle size

-

Magnetic intensity calculated based on separation requirement

-

Material Selection:

-

Non-magnetic stainless steel for housing and contact parts

Rubber or PU-coated rollers for wear resistance

-

-

Fabrication:

-

Precision machining of roller shafts and bearing housings

-

Assembly of multiple magnetic poles around the roller shaft

-

Integration of feed hopper, splitter blades, and product outlets

-

-

Testing & Calibration:

-

Gauss testing (typically 12,000 to 20,000 Gauss)

-

Flow testing for different granular/powder materials

-

Final inspection for finish, alignment, and operation

-

Where Itís Used

Magnetic Roller Separators are used in:

-

Mineral Processing Plants (Quartz, Feldspar, Silica Sand)

-

Food Processing (Grains, Pulses, Spices)

-

Ceramics Industry

-

Glass Manufacturing

-

Recycling Plants (Plastic, E-waste)

-

Powder Chemical Industries

-

Abrasives and Refractory Industry

Key Features

-

Magnetic field strength up to 20,000 Gauss

-

Multi-stage magnetic roller configurations (Single, Double, Triple)

-

Available in widths from 100 mm to 1500 mm

-

Adjustable feed control and splitter plates

-

Easy-to-clean magnetic surface

-

Compact and dust-proof enclosure design

-

Low maintenance and continuous operation

Importance

-

Removes iron, steel, and weakly magnetic particles from raw material

-

Ensures purity and quality of processed material

-

Prevents damage to downstream equipment

-

Complies with food, pharma, and industrial standards

Advantages

-

High Efficiency: Removes even very fine iron particles (as small as 15 microns)

-

Energy Efficient: No external power needed for magnetic field

-

Low Maintenance: No moving parts except the rotating roller

-

Easy Installation: Plug-and-play design

-

Customizable Design: Tailored for material type and throughput

-

Corrosion Resistant: Made with SS304/SS316 contact parts

Significance in Industrial Processing

-

Crucial for product purity in export-grade minerals, food, and pharma

-

Enhances operational efficiency by reducing machine wear

-

Supports environmental compliance in recycling and waste processing

-

Part of critical quality control systems in high-value manufacturing

Why Choose Magnetic Roller Separator Exporters from India?

-

Global Standards (CE/ISO certified machines)

Custom Engineering for specific applications

-

Availability of Spares & Support

-

Quick Export Dispatch & Documentation

FAQs

-

What is the maximum magnetic intensity available?

Up to 20,000 Gauss for high-purity separation. -

What material sizes can it handle?

Typically 0.1 mm to 5 mm (fine powders to granules). Can it separate non-ferrous metals?

No. It is specifically for ferrous and paramagnetic contaminants.-

What is the power requirement?

Only for the motor driving the roller; the magnetic field requires no power. -

Is it suitable for food-grade applications?

Yes. With SS316L contact parts and FDA-compliant design. -

How many rollers are typically used?

Single to triple-stage depending on material purity requirement. -

Can it be used continuously?

Yes, it is designed for 24/7 industrial operation. Does it work for moist or sticky materials?

Best suited for dry and free-flowing materials; special models available for slightly moist materials.-

What are typical sizes available?

Widths range from 100 mm to 1500 mm; custom sizes available. Is customization available for export needs?

Yes. Exporters provide voltage/frequency compatibility, language-specific manuals, and CE/GMP compliance.

Conclusion

A Magnetic Roller Separator is a critical investment for industries that demand high-purity raw material. Whether itís silica sand for glass, pulses for food, or quartz for electronics, this machine ensures that your product is free from iron impurities, enhancing its commercial value and process efficiency.

Indian manufacturers are well-equipped with the technology, expertise, and export capabilities to supply world-class magnetic roller separators that are efficient, reliable, and affordable.

Gmail:-jyotimagnet85@gmail.com

Webside:-https://jyotimagnets.com/

Filter Using Tags

Our Blogs

- Magnetic Destoner Exporter from Ahmedabad

- Trusted Magnetic Roll Separator Manufacturer in India

- Leading Magnetic Destoner Supplier in Gujarat

- Best Magnetic Roll Separator Manufacturer in Ahmedabad

- Magnetic Destoner Machine Supplier Gujarat

- Magnetic Destoner for Grain Cleaning Ahmedabad

- Industrial Magnetic Destoner Manufacturer in India

- Magnetic Destoner Supplier in Gujarat

- Magnetic Destoner Manufacturer in Ahmedabad

- Magnetic Roll Separator for Mineral Processing Gujarat

- Rare Earth Magnetic Roll Separator Manufacturer Ahmedabad

- High-Intensity Magnetic Roll Separator Manufacturer in India

- Magnetic Roll Separator Supplier in Gujarat

- Magnetic Roll Separator Manufacturer in Ahmedabad

- Top Magnetic Separator Drum Manufacturer in Gujarat

- Magnetic Drum Separator Exporter from Ahmedabad

- Trusted Magnetic Drum Separator Manufacturer in India

- Leading Magnetic Drum Separator Supplier in Gujarat

- Best Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Manufacturer in Gujarat

- Heavy Duty Magnetic Drum Separator Supplier Ahmedabad

- Magnetic Drum Separator Machine Manufacturer India

- Industrial Magnetic Drum Separator Supplier Gujarat

- Magnetic Separator Drum Manufacturer Ahmedabad

- Automatic Magnetic Drum Separator Manufacturer in India

- Magnetic Drum Separator Supplier in Gujarat

- Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Equipment Supplier

- Best Magnetic Separator Manufacturer in China

- Magnetic Roller Separator Exporter from India

- Magnetic Roll Separator Manufacturer in Gujarat

- Rare Earth Magnetic Separator

- High Intensity Magnetic Separator Supplier

- Magnetic Roll Separator

- Magnetic Roller Separator Machine?

- High Intensity Magnetic Separator Manufacturer

- Magnetic Roll Separator Manufacturer

- Dry Magnetic Separator

- High Intensity Magnetic Separator

- Magnetic Roller Separator

- Magnetic Rods Price

- Top Magnetic Rod Manufacturers

- Vibro Sifter Machine Exporter in Gujarat

- Industrial Vibro Destoner Machine

- Vibro Destoner Machine

- Automatic Vibro Destoner Machine in Ahmedabad

- Magnetic Destoner Machine Manufacturer

- Automatic Magnetic Destoner

- Hopper Magnet Manufacturer in Ahmedabad

- Magnetic Destoner Machine

- Magnetic Destoner Rod

- Magnetic Destoner Manufacturers

- Magnetic Destoner Price & Overview

- Magnetic Destoner Manufacturers Near Me

- Magnetic Destoner Manufacturers in Ahmedabad

- Magnetic Destoner Manufacturers in India

- Magnetic Destoner Manufacturer

- Leading Industrial Magnetic Equipment Manufacturer in Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Efficient Vibro Sieves Manufacturer in India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Durable Drum Pulleys Exporter from Ahmedabad

- Reliable Suspension Magnet Manufacturer in India

- High-Quality Gyro Screen Machines Supplier in Gujarat

- Magnetic Separator for Industrial Use in Ahmedabad

- Magnetic Plate and Rod Supplier in Ahmedabad

- Suspension Magnet Exporter From Ahmedabad

- Gyro Screen Machine Supplier in Gujarat

- Magnetic Equipment Manufacturer in Ahmedabad

- Magnetic Rod Supplier in Ahmedabad

- Magnetic Bar Manufacturer in India

- Industrial Magnetic Equipment Manufacturer Ė Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Vibro Sieve Manufacturer India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Vibro Sifter Manufacturer

- Gyro Screen Machine

- Vibro Sieve

- Vibro Screen

- Magnetic Grill

- Magnetic Tube

- Magnetic Bar

- Magnetic Rod

- Magnetic Destoner

- Magnetic Roll Separator

- Magnetic Drum Separator

- Overband Magnetic Separator

- Top Pipeline Magnet Products

- Gyro Screen Machine

- Vibro Screen

- Magnetic roll separator magnetic destoner

- Magnetic Drum Separator

- High Power Magnetic Rod

- Industrial Suspension Magnet

- Hopper Magnetic Grill

- Plate Magnet

- Magnetic Rod Manufacturers

- Super Magnetic Plate Suppliers

- Super Magnetic Plate

- Magnetic Plates Exporters

- Magnetic Plates Manufacturers Andhra Pradesh

- Magnetic Rod Suppliers

- Magnetic Rod Company

- Magnetic Plate Manufacturer

- Strong Magnetic Rod

- Magnetic Plate

- Magnetic Rod Price Manufacturer

- Magnetic Rod

- Heavy Duty Industrial Magnets

- Suspended Magnets Dealer

- Suspension Magnet Supplier

- Suspension Magnet Manufacturer

- Suspension Magnetic Separator

- Suspension Permanent Magnets

- Industrial Magnetic Grill

- Grill Magnet Manufacturer Mizoram

- Magnetic Grill Manufacturer

- Hopper Magnetic Grill

- Power Magnetic Grill

- Magnetic Grill