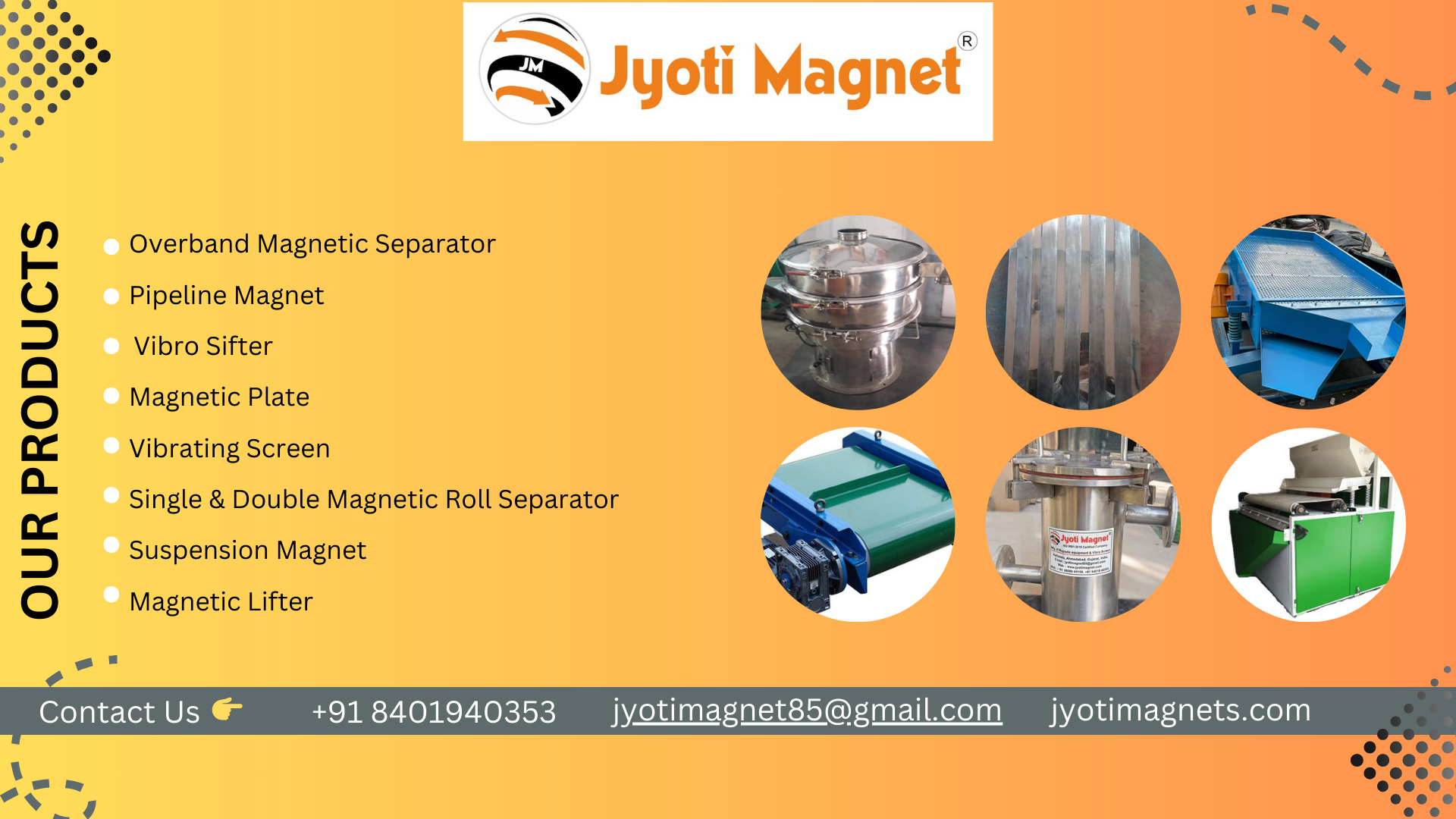

Magnetic Destoner Manufacturers in India

Magnetic

Destoner Manufacturers in India

Magnetic Destoner Manufacturers in India are leading

producers and exporters of highly efficient machines used for removing ferrous

metal impurities and stones from dry granular materials like rice, wheat,

spices, pulses, coffee beans, minerals, and plastics. These machines combine magnetic

separation and gravity-based destoning for precise material purification.

Indian manufacturers—especially based in Gujarat (Rajkot,

Ahmedabad), Tamil Nadu (Coimbatore), and Madhya Pradesh (Indore)—are known

for engineering robust, energy-efficient, and export-grade Magnetic Destoners

using rare-earth magnets, vibratory trays, and custom air flow

technology. They offer standard and customized models with capacities from 1

TPH to 25+ TPH, suitable for diverse industrial applications.

Features

of Magnetic Destoner (with Uses)

|

Feature |

Use / Benefit |

|

High-Intensity Rare Earth Magnets |

Removes even micro ferrous particles from the material stream. |

Adjustable Vibratory Feed Deck |

Ensures uniform material flow for optimal separation

performance. |

|

Air Suction System (Optional) |

Enhances separation of lighter and heavier contaminants. |

|

Stainless Steel Contact Parts (SS 304/316) |

Ensures food-grade hygiene and long-term corrosion

resistance. |

|

Multi-Layer Separation Technology |

Increases purity by removing both ferrous and non-ferrous

stones simultaneously. |

|

Custom Output Capacity (1–25 TPH) |

Suits small mills to large industrial processing plants. |

|

Compact and Modular Design |

Easy to integrate into existing processing lines. |

|

Low Noise and Power Consumption |

Environment-friendly, efficient operation with minimal

maintenance. |

Applications

of Magnetic Destoners in India

- Rice

Mills – Remove iron dust, stones, and ferrous contaminants from raw and polished rice.

- Wheat

and Flour Processing Units – Clean wheat before grinding to protect

machinery.

- Spice

Processing Plants – Ensure purity in products like turmeric,

coriander, cumin, etc.

- Pulse

and Dal Mills – Clean lentils and other pulses for safe consumption.

- Coffee

and Cocoa Processing – Eliminate metallic and stone impurities in

high-value beans.

- Mineral

Industries – Used in quartz, silica, and feldspar processing to remove

iron impurities.

- Plastic

Granule Units – Clean plastic resins and granules from iron and

metallic dust.

- Chemical

& Fertilizer Plants – Filter powders and granules for

contaminant-free output.

- Oilseed

Processing – Protect expellers and increase oil purity by removing

metallic bits.

- Feed

Manufacturing Units – Ensure safe and pure animal feed free from

contaminants.

Key

Points – Magnetic Destoner Manufacturers in India

- Top

Manufacturing Hubs: Rajkot, Ahmedabad, Coimbatore, Indore, Noida.

- Capacity

Range: Available in 1 TPH to 25+ TPH.

- Technology

Used: Rare earth magnets, vibrating deck, and air classification.

- Export-Ready

Machines: CE certified, ISO 9001:2015 compliant units.

- Customization:

Available for material type, magnet strength, deck design, and frame.

- Food-Grade

Materials: SS contact parts for hygienic processing.

- Eco-Friendly:

No chemical use, low energy, and reduced material waste.

- After-Sales

Support: Spare parts, AMC, installation, and training offered.

- Industries

Served: Food, minerals, plastics, agriculture, fertilizer, chemicals.

- Competitive

Pricing: Indian manufacturers offer global-standard machines at

cost-effective rates.

Top 10

FAQs – Magnetic Destoner Manufacturers in India

1. What does a magnetic destoner do?

2. Which Indian cities are known for magnetic destoner

manufacturers?

Cities like Rajkot, Ahmedabad, Coimbatore, and Indore

are well-known manufacturing hubs.

3. Are Indian magnetic destoners food-grade compliant?

Yes, most machines are made with SS 304/316 contact

parts and adhere to food safety standards.

4. What capacity machines are available in India?

Manufacturers offer machines from 1 TPH (small mills)

to 25+ TPH (large plants).

5. Do manufacturers in India provide export services?

Yes, many Indian manufacturers export to Africa, Middle

East, Europe, and Southeast Asia.

6. Can I customize the machine for specific materials?

Yes, customization is available in magnet strength,

airflow, size, and deck design.

7. What power does the machine consume?

Depending on size, power usage ranges from 1.5 HP to 7.5

HP.

8. How do I maintain the magnetic destoner?

Regular cleaning of the magnet chamber and deck is required;

minimal maintenance needed otherwise.

9. Are spare parts and service easily available?

Yes, leading manufacturers offer full after-sales

service, spare parts, and AMC contracts.

10. How much does a magnetic destoner cost in India?

Prices vary by model and capacity, typically ranging from ?90,000

to ?5,00,000+.

Contact

Us For More Details On :

Call - +91 84019 40353

Facebook - www.facebook.com/JyotiMagnet

Instagram - www.instagram.com/jyotimagnet_india

YouTube - www.youtube.com/@jyotimagnet1587

Website – www.jyotimagnets.com

Email - jyotimagnet85@gmail.com

Filter Using Tags

Our Blogs

- Magnetic Destoner Exporter from Ahmedabad

- Trusted Magnetic Roll Separator Manufacturer in India

- Leading Magnetic Destoner Supplier in Gujarat

- Best Magnetic Roll Separator Manufacturer in Ahmedabad

- Magnetic Destoner Machine Supplier Gujarat

- Magnetic Destoner for Grain Cleaning Ahmedabad

- Industrial Magnetic Destoner Manufacturer in India

- Magnetic Destoner Supplier in Gujarat

- Magnetic Destoner Manufacturer in Ahmedabad

- Magnetic Roll Separator for Mineral Processing Gujarat

- Rare Earth Magnetic Roll Separator Manufacturer Ahmedabad

- High-Intensity Magnetic Roll Separator Manufacturer in India

- Magnetic Roll Separator Supplier in Gujarat

- Magnetic Roll Separator Manufacturer in Ahmedabad

- Top Magnetic Separator Drum Manufacturer in Gujarat

- Magnetic Drum Separator Exporter from Ahmedabad

- Trusted Magnetic Drum Separator Manufacturer in India

- Leading Magnetic Drum Separator Supplier in Gujarat

- Best Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Manufacturer in Gujarat

- Heavy Duty Magnetic Drum Separator Supplier Ahmedabad

- Magnetic Drum Separator Machine Manufacturer India

- Industrial Magnetic Drum Separator Supplier Gujarat

- Magnetic Separator Drum Manufacturer Ahmedabad

- Automatic Magnetic Drum Separator Manufacturer in India

- Magnetic Drum Separator Supplier in Gujarat

- Magnetic Drum Separator Manufacturer in Ahmedabad

- Magnetic Separator Equipment Supplier

- Best Magnetic Separator Manufacturer in China

- Magnetic Roller Separator Exporter from India

- Magnetic Roll Separator Manufacturer in Gujarat

- Rare Earth Magnetic Separator

- High Intensity Magnetic Separator Supplier

- Magnetic Roll Separator

- Magnetic Roller Separator Machine?

- High Intensity Magnetic Separator Manufacturer

- Magnetic Roll Separator Manufacturer

- Dry Magnetic Separator

- High Intensity Magnetic Separator

- Magnetic Roller Separator

- Magnetic Rods Price

- Top Magnetic Rod Manufacturers

- Vibro Sifter Machine Exporter in Gujarat

- Industrial Vibro Destoner Machine

- Vibro Destoner Machine

- Automatic Vibro Destoner Machine in Ahmedabad

- Magnetic Destoner Machine Manufacturer

- Automatic Magnetic Destoner

- Hopper Magnet Manufacturer in Ahmedabad

- Magnetic Destoner Machine

- Magnetic Destoner Rod

- Magnetic Destoner Manufacturers

- Magnetic Destoner Price & Overview

- Magnetic Destoner Manufacturers Near Me

- Magnetic Destoner Manufacturers in Ahmedabad

- Magnetic Destoner Manufacturers in India

- Magnetic Destoner Manufacturer

- Leading Industrial Magnetic Equipment Manufacturer in Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Efficient Vibro Sieves Manufacturer in India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Durable Drum Pulleys Exporter from Ahmedabad

- Reliable Suspension Magnet Manufacturer in India

- High-Quality Gyro Screen Machines Supplier in Gujarat

- Magnetic Separator for Industrial Use in Ahmedabad

- Magnetic Plate and Rod Supplier in Ahmedabad

- Suspension Magnet Exporter From Ahmedabad

- Gyro Screen Machine Supplier in Gujarat

- Magnetic Equipment Manufacturer in Ahmedabad

- Magnetic Rod Supplier in Ahmedabad

- Magnetic Bar Manufacturer in India

- Industrial Magnetic Equipment Manufacturer – Gujarat

- Magnetic Grill Supplier in Ahmedabad

- Vibro Sieve Manufacturer India

- Magnetic Plate and Rod Manufacturer in Gujarat

- Vibro Sifter Manufacturer

- Gyro Screen Machine

- Vibro Sieve

- Vibro Screen

- Magnetic Grill

- Magnetic Tube

- Magnetic Bar

- Magnetic Rod

- Magnetic Destoner

- Magnetic Roll Separator

- Magnetic Drum Separator

- Overband Magnetic Separator

- Top Pipeline Magnet Products

- Gyro Screen Machine

- Vibro Screen

- Magnetic roll separator magnetic destoner

- Magnetic Drum Separator

- High Power Magnetic Rod

- Industrial Suspension Magnet

- Hopper Magnetic Grill

- Plate Magnet

- Magnetic Rod Manufacturers

- Super Magnetic Plate Suppliers

- Super Magnetic Plate

- Magnetic Plates Exporters

- Magnetic Plates Manufacturers Andhra Pradesh

- Magnetic Rod Suppliers

- Magnetic Rod Company

- Magnetic Plate Manufacturer

- Strong Magnetic Rod

- Magnetic Plate

- Magnetic Rod Price Manufacturer

- Magnetic Rod

- Heavy Duty Industrial Magnets

- Suspended Magnets Dealer

- Suspension Magnet Supplier

- Suspension Magnet Manufacturer

- Suspension Magnetic Separator

- Suspension Permanent Magnets

- Industrial Magnetic Grill

- Grill Magnet Manufacturer Mizoram

- Magnetic Grill Manufacturer

- Hopper Magnetic Grill

- Power Magnetic Grill

- Magnetic Grill